Published on : 11 December 2025

A Business Owner's Guide To Wholesale Packaging Supplies UK

Choosing the right wholesale packaging supplies in the UK is about more than just ticking a box on your to-do list—it's a critical part of your business strategy. Get it right, and your packaging protects your products, creates a brilliant unboxing experience, and shows your customers you’re serious about quality. This guide will show you how to turn a simple cost into a real competitive advantage.

Why Your Packaging Strategy Is A Competitive Advantage

Too many businesses see packaging as just a necessary expense—a box to get something from A to B. But looking at it that way misses a huge opportunity. Especially in e-commerce, your packaging is often the very first physical interaction a customer has with your brand. It’s a tangible piece of your marketing, a silent salesperson, and the guardian of your goods.

Think of it this way: a flimsy, poorly sealed box that shows up battered and bruised doesn't just put the product at risk; it damages customer trust before they've even opened it. On the flip side, a sturdy, well-presented package screams professionalism and care, boosting the perceived value of what’s inside. That first impression sets the stage for customer loyalty and repeat business.

More Than Just A Box

A smart approach to packaging delivers real benefits that directly affect your bottom line and your reputation. Investing in the right supplies is an investment in your business's future.

Here’s what you stand to gain:

- Enhanced Product Protection: Getting this right cuts down on damages and returns, saving you a fortune in replacements, extra shipping costs, and customer service time.

- Improved Brand Perception: Quality packaging creates a premium feel, reinforcing your brand’s commitment to excellence and justifying your price point.

- A Memorable Unboxing Experience: A great unboxing moment can generate free social media buzz and word-of-mouth marketing, turning happy customers into brand advocates.

- Operational Efficiency: The right supplies, from easy-to-assemble boxes to reliable tape, make your packing process quicker and smoother, saving you valuable time.

This growing focus is reflected in the market's size. The UK packaging industry was valued at roughly USD 35.6 billion in 2024 and is set to grow significantly, thanks to the boom in e-commerce and customer demand for both quality and sustainability. You can discover more insights about UK packaging market trends over on imarcgroup.com.

Choosing your packaging supplier is as important as choosing your products. A reliable partner ensures you have consistent quality, fair pricing, and expert guidance, which is fundamental for scaling your operations smoothly.

Ultimately, your packaging choices tell a story about your brand. By understanding the core principles of selecting wholesale packaging supplies, you can make sure that story is one of quality, reliability, and happy customers. We explain more about the top reasons customers trust our service in our dedicated article.

Understanding The Core Types Of Packaging Supplies

To run a truly cost-effective and efficient packing operation, you first need to get to grips with the fundamental tools of the trade. Think of it like a professional chef's kitchen; you need the right ingredients and equipment to create the perfect dish. In the same way, choosing the right wholesale packaging supplies in the UK is what ensures your products arrive in one piece, your brand looks the part, and your team isn't wasting time.

Let's break down the essential building blocks of any packing strategy. We’ll go beyond a simple shopping list to really explore the ‘why’ behind each choice, helping you see how these core items work together to form a complete protective bubble around your goods.

The Foundation: Cardboard Boxes

Cardboard boxes are the undisputed workhorses of the packaging world. They are your primary container, the first line of defence, and the main structure holding everything together on its journey. But here's the thing: not all boxes are created equal, and choosing the right type is the single most critical decision you'll make.

The main difference comes down to the wall construction:

- Single-Wall Boxes: Made from one layer of corrugated cardboard, these are lightweight, affordable, and perfect for shipping lighter, less fragile items like clothing, books, or non-perishable goods. Think of them as the reliable family car—great for everyday journeys.

- Double-Wall Boxes: These are built with two layers of corrugated board, giving them a massive boost in strength and rigidity. This "double-armour" approach makes them the go-to choice for heavier or more delicate products, like electronics, glassware, and machine parts. They're also essential for stacking in a warehouse or during a house move, as they resist crushing far better.

Getting the wall type right has a direct impact on product safety. Using a single-wall box for a heavy item is a recipe for disaster, while over-specifying a double-wall box for a light T-shirt just means you're spending more than you need to. You can find a huge variety of both single and double-wall cardboard boxes to find the perfect match for your products.

The Cushioning: Protective Materials

Once your product is in the box, all that empty space around it becomes a hazard zone. In transit, items can shift, rattle, and collide with the inner walls, leading to scuffs, scratches, or even complete breakage. This is where protective materials, often called void fill, earn their keep. Their job is simple: to absorb shock and stop the contents from moving.

Imagine you’re packing a delicate vase. You wouldn't just drop it in a box and hope for the best, would you? You’d surround it with cushioning to shield it from bumps and drops.

The goal of protective material is to create a "crumple zone" inside your package, much like the one in a car. It's designed to absorb impact energy so that your product doesn't have to.

Here are the most common choices on the market:

- Bubble Wrap: A classic for a reason. Bubble wrap provides fantastic cushioning for fragile items. Its air-filled pockets absorb shock brilliantly, making it perfect for wrapping individual products like ceramics, picture frames, and electronics.

- Packing Paper: This is a hugely versatile and eco-friendly option. You can scrunch it up to fill voids or use it to wrap items and prevent surface scratches. It’s especially useful for separating multiple items packed within the same box.

- Air Pillows: These are plastic bags inflated with air, offering a super lightweight way to fill large empty spaces inside a box. They are incredibly light, which can help keep your shipping costs down, but they offer less direct cushioning for items with sharp corners compared to bubble wrap.

The right choice really depends on the product's fragility, weight, and shape. Often, a combination is the best strategy—wrapping an item in paper to prevent scratches, then cushioning it with bubble wrap before filling any remaining space with air pillows.

The Seal: Securing Supplies

Your packaging is only as strong as its weakest point, which is very often the seal. A securely packed box that pops open mid-transit is a total failure, no matter how sturdy the cardboard or how much bubble wrap you’ve used. This final stage is all about making sure everything stays contained from your warehouse right to the customer's doorstep.

The two main players in this category are packing tape and pallet wrap.

Packing Tape is the final lock on your individual parcels. A high-quality adhesive tape ensures your box flaps stay firmly closed, reinforcing the box's structural integrity. Cheap tape that peels away easily not only risks the package opening but also makes the whole parcel look unprofessional and untrustworthy.

Pallet Wrap, also known as stretch film, is what you use to secure multiple boxes together on a pallet for bulk shipment. It binds the entire load tightly, stopping boxes from shifting or toppling over during transport by lorry. It also offers a decent degree of protection against moisture and dust.

To help you match your business needs to the right supplies at a glance, this quick guide breaks down the most common use cases.

Packaging Product Selection Guide

| Business Need | Recommended Packaging Supply | Primary Use Case |

|---|---|---|

| Shipping lightweight goods | Single-Wall Cardboard Boxes | E-commerce orders for clothing, books, or non-fragile items. |

| Protecting heavy or fragile items | Double-Wall Cardboard Boxes | Transporting electronics, glassware, kitchenware, or for house removals. |

| Cushioning delicate products | Bubble Wrap | Wrapping individual fragile items like ornaments, ceramics, and photo frames. |

| Filling empty space in boxes | Packing Paper or Air Pillows | Preventing items from moving inside the box during transit to avoid damage. |

| Securing multiple boxes for freight | Pallet Wrap (Stretch Film) | Stabilising a full pallet of boxes for safe and secure bulk shipment. |

| Sealing individual parcels | High-Adhesion Packing Tape | Ensuring boxes remain securely closed from dispatch to delivery. |

This table should make it easier to see how these core components fit together to build a reliable packaging system.

Beyond these primary containers, don't forget essential add-ons like custom product labels for packaging, which are crucial for branding and displaying important product information. By mastering these three core categories—boxes, protection, and securing supplies—you create a complete system that safeguards your products and enhances your brand.

How To Choose The Right Material Strength For Your Products

Getting the material strength of your packaging right isn’t just a technical detail; it's the secret to dodging costly damages, frustrating returns, and a dent in your brand’s reputation. Think of it as choosing the right armour for your products before they head into battle on the delivery network. Go too tough, and you’re wasting money. Underestimate the risks, and your goods pay the price.

This whole process can feel a bit confusing, especially with industry jargon like "board grades" and "GSM" floating around. But honestly, the core ideas are pretty straightforward. Once you grasp a few key principles, you can do a quick audit of your products and shipping conditions to pick packaging that offers perfect protection without breaking the bank.

From Single To Double Wall: A Simple Analogy

The most fundamental choice you'll make is the box wall construction. Each type offers a different level of protection, a bit like layers of clothing on a cold day. One layer might be fine for a mild afternoon, but you'll want something more substantial for a proper winter storm.

- Single-Wall Boxes: This is your basic layer. Made from one sheet of corrugated cardboard, it’s ideal for lightweight, durable items that aren’t easily broken. Think clothing, books, or soft goods.

- Double-Wall Boxes: This is like adding a sturdy jacket. With two layers of corrugated board and an extra liner in between, these boxes are significantly more rigid and crush-resistant. They’re the go-to for heavier or moderately fragile items like electronics, kitchenware, or for stacking during a house move.

For most businesses shipping a variety of goods, exploring a range of sturdy double-wall boxes is the best place to start. They provide that reliable sweet spot between protection and cost. Triple-wall boxes do exist, offering maximum-duty protection for incredibly heavy industrial parts, but they’re usually overkill for general e-commerce or moving needs.

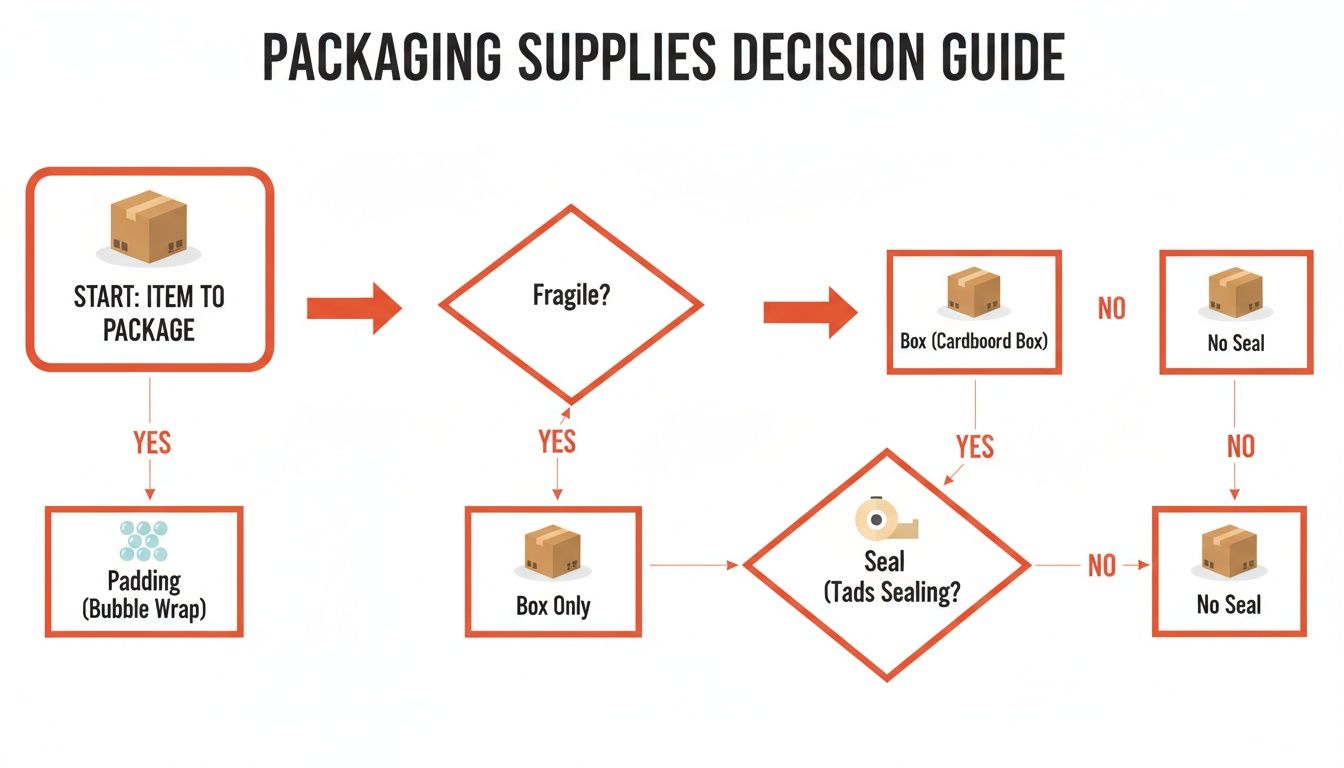

This decision tree gives you a simple visual guide to help you choose the right packaging supplies based on what your item needs.

As the flowchart shows, it’s a logical journey from picking the right box, to choosing the right padding, and making sure it’s all sealed up securely.

Decoding Board Grades And GSM

Beyond the number of walls, the actual quality of the cardboard itself plays a huge part. This is where you’ll hear terms like "board grade" and "GSM". They sound technical, but they're really just simple measurements of durability.

GSM (Grams per Square Metre) tells you the weight and density of the paper used to make the box. A higher GSM generally means a stronger, more puncture-resistant board. It’s like comparing a flimsy piece of paper to a thick piece of card; the card is heavier and much harder to tear.

Think about the journey your parcel will take. A single item sent with a careful courier might be fine in a standard box. But a whole pallet of goods rattling around in the back of a lorry needs much more structural integrity to survive the trip.

The UK's demand for robust materials is clear. In 2024, packaging material consumption in the UK was around 3.4 million tons. This figure shows the sheer volume of goods being moved and highlights just how critical the right material strength is to get them there safely.

A Quick Product Protection Audit

You don't need to be a packaging engineer to make the right choice. You just need to ask yourself three simple questions about your products:

- How heavy is it? The heavier the item, the more strain it puts on the box, especially the base. Heavy items demand double-wall boxes as a minimum.

- How fragile is it? Delicate things like glass or ceramics need a combination of a strong outer box and plenty of internal cushioning to absorb any shocks.

- What are the shipping conditions? Will it be stacked high in a warehouse? Handled by multiple couriers? The rougher the journey, the stronger the box needs to be.

Answering these questions honestly will guide you straight to the perfect material strength every time, ensuring your products are protected and your customers are happy.

Time To Talk About Sustainable And Eco-Friendly Packaging

Today's customers are sharper than ever. They don't just buy a product; they buy into a brand's entire way of doing things, and that absolutely includes its attitude towards the environment. Choosing eco-friendly wholesale packaging supplies in the UK has shifted from a nice-to-have bonus to a core expectation that can genuinely shape what people think of your business.

This means we have to look beyond just whether a box is strong enough. Making a conscious choice to use sustainable materials sends a clear signal: your company cares about its footprint. It's a move that pulls in and keeps customers who share those values, turning your parcels into a statement of responsibility.

Getting The Lingo Right

Diving into sustainable packaging can feel a bit confusing, especially with all the different terms being thrown around. Understanding what they actually mean is the key to making genuinely green choices and avoiding "greenwashing" – making vague or misleading claims about your eco-credentials.

Let's clear up the main ones:

- Recyclable: This is straightforward. It means the material can be broken down and remade into something new. Cardboard is the perfect example; it gets pulped and reformed into new boxes, which cuts down on the need for virgin materials.

- Biodegradable: This just means the material can be broken down over time by natural things like bacteria. The catch? The conditions and timescale can vary wildly.

- Compostable: This is much more specific. Compostable materials break down into natural elements in a proper compost environment, leaving no toxic bits behind. This process is usually much faster and cleaner than general biodegradation.

Honestly, for most businesses, sticking with recyclable materials like cardboard and paper is the most practical and impactful way to go. The UK has a fantastic recycling infrastructure already in place, making it simple for your customers to do the right thing with your packaging.

By choosing materials that are widely and easily recycled, you're not just making a sustainable choice for your business; you're making it simple for your customers to be part of the solution.

Practical Green Alternatives That Actually Protect

Going green doesn't mean compromising on protection. Not anymore. Modern eco-friendly supplies are engineered to be every bit as tough and reliable as their traditional counterparts, making sure your products arrive safe and sound while hitting your environmental targets. It's all about picking the right tool for the job.

Here are some of the most popular and effective options we see people using every day:

- Recycled Cardboard Boxes: The absolute cornerstone of any green packing strategy. Using boxes made with a high percentage of recycled content is a simple but powerful switch.

- Paper-Based Void Fill: Instead of plastic air pillows or those messy polystyrene peanuts, use scrunched-up packing paper or clever honeycomb paper wrap to cushion items and fill any gaps.

- Paper Tapes: A brilliant alternative to standard plastic parcel tape. Gummed paper tape creates a seriously strong, tamper-evident seal and can be recycled right along with the cardboard box.

These alternatives don't just slash your plastic waste; they can bring some unexpected perks, too. Paper-based void fill, for example, is often supplied flat-packed, which saves a huge amount of precious warehouse space compared to bulky rolls of bubble wrap. Our guide to eco-friendly moving practices is packed with more tips like this for reducing your impact.

Using these materials shows a real commitment to sustainability that clicks with modern shoppers. It's a smart decision that protects your products, boosts your brand, and does a little bit of good for the planet.

Unlocking Cost Savings Through Bulk Buying And Smart Logistics

Optimising your packaging budget is one of the most direct ways to improve your bottom line. Moving beyond small, frequent orders and embracing a wholesale mindset lets you unlock some serious financial advantages. This isn't just about buying more boxes; it's about strategically managing how you buy and receive your supplies to drive down the cost of every single parcel you send out.

Think of it like doing your weekly shop. Buying a single tin of beans is handy, but it costs more per unit than buying a multipack. The same principle applies to wholesale packaging supplies uk. Suppliers offer tiered pricing where the cost per item drops dramatically as your order volume goes up. By planning ahead, you can tap into these lower price brackets and make your budget stretch a whole lot further.

The Power Of Forecasting And Bulk Discounts

The first step to getting the most out of wholesale pricing is getting decent at forecasting. This just means looking at your sales data from previous months or seasons to predict how many boxes, rolls of tape, and other supplies you'll realistically need. A good forecast stops two major headaches: running out of stock during a busy period, or tying up too much cash in excess inventory that just sits in your warehouse gathering dust.

Once you have a solid forecast, you can start placing larger, less frequent orders.

- Lower Per-Unit Costs: Buying in bulk directly reduces the price you pay for each individual box or roll of bubble wrap.

- Reduced Shipping Fees: Fewer, larger deliveries mean you pay for transport less often, cutting down on your overall shipping spend.

- Time Savings: Less time spent placing orders and taking in deliveries means your team can focus on more productive tasks, like getting orders out the door.

This strategy is especially powerful for the booming e-commerce sector. The UK market for custom packaging, for example, is projected to hit USD 5.68 billion in 2025. A huge chunk of this growth is driven by businesses scaling up and needing more efficient, cost-effective supply chains.

Smart Logistics: The Other Half Of The Equation

Bulk buying saves you money on the products themselves, but smart logistics saves you money on everything else. A supplier’s delivery promise is a critical part of the value they offer. Partnering with a wholesaler that provides reliable, next-day UK dispatch is a huge strategic advantage.

Your supplier’s warehouse effectively becomes an extension of your own. Fast, dependable delivery means you don't need to hold vast amounts of stock on-site, freeing up valuable space and capital.

This "just-in-time" approach to inventory keeps your operation lean and agile. You can order what you need with the confidence that it will arrive promptly, ensuring you never face a packaging shortage that could grind your entire dispatch process to a halt. This efficiency is a core part of effective supply chain management. For a deeper dive, exploring various supply chain cost reduction strategies can provide further practical insights for your business.

By combining intelligent bulk purchasing with a logistics-focused supplier, you create a powerful system that minimises costs and maximises how efficiently you can run your business. For more information, check out our guide on the benefits of buying trade quality packaging online.

How To Choose The Best Wholesale Packaging Supplier In The UK

Picking the right supplier for your wholesale packaging supplies in the UK is a strategic move that goes way beyond just chasing the lowest price. Your supplier isn’t just another vendor on a spreadsheet; they’re a vital partner in your day-to-day operations. Their performance has a direct knock-on effect on everything from product safety to your customers' happiness.

A great partnership means a reliable flow of quality materials when you need them. A poor one? It's a recipe for constant disruption and headaches.

This means you need a solid framework for sizing up potential partners. It’s all about looking at the complete picture—the quality of their boxes, how reliable their delivery is, what their support is like, and whether their pricing is transparent. The goal is to find a company that actively helps your business grow, not one that just sells you cardboard.

Key Evaluation Criteria For Your Supplier

It’s incredibly easy to get fixated on the cost per box. But while price is obviously important, things like consistent material quality and next-day dispatch have a much bigger impact on your real-world costs and efficiency. A cheap box that fails in transit and leads to a damaged product is far more expensive than a slightly pricier, dependable one.

Use this checklist to properly assess potential suppliers and make a decision you won't regret:

- Comprehensive Product Range: Can you get everything you need from one place? Finding a one-stop shop for boxes, tapes, bubble wrap, and pallet wrap simplifies your purchasing process massively.

- Consistent Material Quality: Is the quality of their double-wall boxes the same from one order to the next? You need to be able to count on that strength to protect your goods. It's non-negotiable.

- Transparent Pricing Structure: Are bulk discounts and tiered pricing clear and easy to understand? You need to know exactly how scaling up your orders will affect your costs.

- Proven Delivery Reliability: Do they offer a dependable next-day dispatch service across the UK? Fast, reliable delivery is absolutely essential for managing your stock and keeping your packing line moving.

Think of your packaging supplier as an extension of your own warehouse. Their ability to deliver high-quality supplies exactly when you need them is fundamental to your ability to serve your own customers effectively.

Looking Beyond The Products

The best suppliers offer a lot more than just physical goods; they bring genuine expertise and support to the table. A partner who really gets the challenges of e-commerce, removals, or storage can offer priceless advice on the right materials and packing techniques for your specific needs.

That level of service is what separates a simple transaction from a real business relationship.

Before you commit, ask yourself a few final questions:

- Is Expert Advice Available? Can you easily get hold of someone for guidance on a tricky packaging problem?

- How Do They Handle Issues? What's their process if an order is wrong or a delivery gets delayed?

- Do They Understand Your Business? Do they cater to businesses of your size and in your industry, whether you're a small online seller or a large removal firm?

Choosing the right partner is an investment in your operational stability. By carefully thinking through these points, you can build a long-term relationship with a supplier who helps you scale, solve challenges, and consistently deliver for your own customers.

Your Wholesale Packaging Questions, Answered

Stepping into the world of wholesale packaging can bring up a few questions, especially when you’re trying to balance cost, quality, and speed. Here are the straight-up answers to some of the most common queries we hear from businesses looking to buy smarter.

What Is The Minimum Order For Wholesale Pricing?

This is the big one, but the honest answer is: it varies. There’s no single rule for wholesale, as every supplier sets their own bar. Most will have a minimum order value (MOV) – say, a spend of £50-£100 – or require you to buy a minimum quantity, like a full pack or a pallet of boxes, to unlock their best trade prices.

The trick is finding a supplier whose setup fits your business. Some are geared towards helping smaller companies with low minimums, while others are set up for high-volume industrial clients. It’s always best to clarify this right at the start to make sure they’re a good match for how you buy.

How Quickly Can I Get My Supplies Delivered?

In today's market, you can't afford to wait around. Any decent UK supplier should offer a next working day dispatch as their standard service, provided you get your order in before their daily cut-off. This is absolutely vital for keeping your own operation running smoothly and avoiding stock shortages that can cost you sales.

But always check the small print:

- Cut-off Times: What’s the final call for getting an order out the same day?

- Postcode Surcharges: Are there extra charges or longer delivery times for remote spots like the Scottish Highlands?

- Pallet Deliveries: Big pallet orders often need a bit more planning and might take an extra day or two (think 2-3 days) to arrive.

A supplier's ability to get your order to you on time, every time, is just as important as the quality of the boxes themselves.

When you're comparing suppliers, don't just see delivery as an add-on; see it as a core feature. A cheap box that shows up late can cause more headaches and lost revenue than one that costs a fraction more but arrives exactly when you need it.

Can I Get Samples Before Placing A Large Order?

You absolutely should. Any supplier of wholesale packaging supplies in the UK worth their salt will be more than happy to send you samples of key items, whether it’s a few different grades of cardboard box or a roll of their packing tape. This is such an important part of the process. It lets you physically test the material's strength and see if it’s the right fit for your products.

Getting samples takes all the guesswork out of buying in bulk. It gives you total confidence before you commit to a big order and is a simple step that can prevent some very expensive mistakes down the line, ensuring the quality you're paying for is the quality you actually get.

At The Box Warehouse, we believe in being upfront and clear about our products, pricing, and delivery. We’re here to help you find the perfect packaging for your business. Take a look at our full range of professional-grade supplies at https://www.theboxwarehouse.co.uk.

Recent Blogs

Where to Buy Boxes in the UK A Complete 2026 Guide

26 Feb 2026

A Complete Guide to Acid-Free Tissue Paper for Moving and Storage

25 Feb 2026

Clothes Storage: Expert UK Guide to Packing, Protecting & Organising

20 Feb 2026

A Practical Guide to Corner Protection for Furniture

20 Feb 2026

The Box Warehouse