Published on : 02 January 2026

A Complete Guide to Corrugated Cardboard Rolls

If you’ve ever tried to protect a large, awkwardly shaped item like a mirror or a tabletop, you’ll know that standard cardboard boxes just don't cut it. It’s a frustrating game of cutting, folding, and taping that never seems to work properly. This is where the simple genius of corrugated cardboard rolls comes in.

Think of it as a versatile 'cardboard quilt',a continuous, flexible sheet of protective packaging you can wrap, cushion, and shield almost anything with. For movers and e-commerce businesses, it's absolutely indispensable.

What Makes Corrugated Cardboard Rolls So Effective?

Unlike rigid sheets or boxes, these rolls offer customisable protection that adapts to the item, not the other way around. You get exactly what you need, every single time.

At its core, the strength of corrugated cardboard comes from its clever, yet simple, structure. The magic is all in the internal wavy layer, known as fluting. This wave-like design creates a series of connected arches that are incredibly effective at absorbing impacts and resisting pressure. This fluted medium is then bonded to a flat linerboard, creating a surprisingly tough yet lightweight barrier.

A Flexible Shield for Any Task

The real value of this stuff is its adaptability. Its continuous length means you can cut precisely the amount you need, dramatically cutting down on waste compared to using fixed-size boxes or sheets. This makes it the go-to solution for a massive range of jobs:

- Surface Protection: Easily cover large areas like wooden floors or countertops during a move or renovation to prevent scratches and dents.

- Wrapping Irregular Items: Provide a cushioned layer for furniture, artwork, or industrial parts that just won't fit into a standard box.

- Void Fill and Cushioning: Crumple it up to fill empty spaces in boxes, stopping items from shifting and bashing into each other during transit.

This unique combination of strength and flexibility is precisely why corrugated rolls are a staple in warehouses and removal vans all across the UK. For similar cushioning needs, many also turn to other materials, and you can learn more about the benefits of bubble wrap in our detailed guide. It’s a fundamental tool for anyone who is serious about protecting their goods.

By offering a continuous, cut-to-size protective layer, corrugated rolls solve one of the biggest challenges in packaging: efficiently protecting items that don’t conform to standard box dimensions.

Understanding Flute Profiles and Material Strength

The real magic of corrugated cardboard rolls is hidden in their construction. It’s a brilliantly simple piece of engineering that turns lightweight paper into a surprisingly strong and protective material. Every roll is essentially a sandwich made of at least two parts: a flat sheet called linerboard and a wavy, arched layer known as the fluting.

It’s this simple pairing of a flat surface with a supportive wave that gives the material its rigidity and cushioning power. Think of it like a Roman aqueduct; the series of arches in the fluting distributes pressure and absorbs knocks far better than a single flat sheet of card ever could. This structure is the absolute key to its performance.

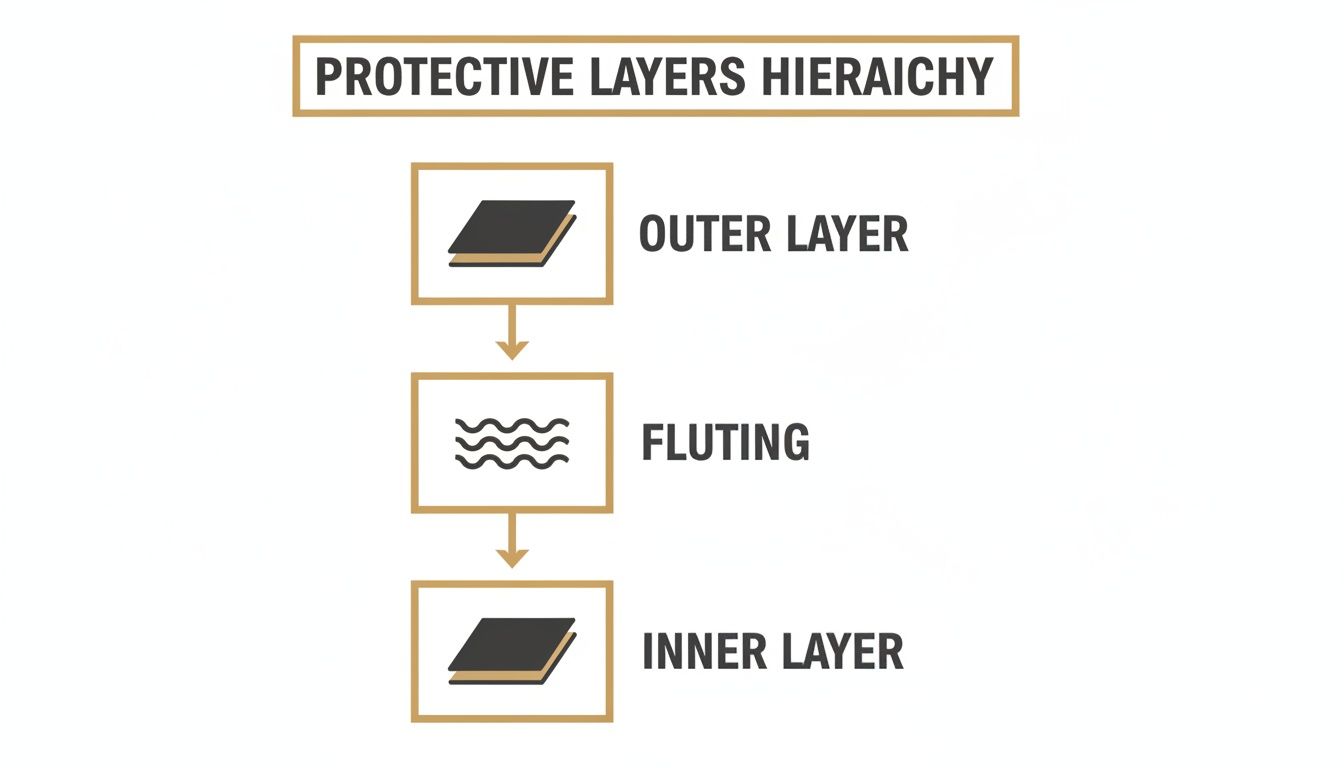

The diagram below breaks down this basic but highly effective three-layer structure.

As you can see, the inner fluting creates tiny air pockets that provide insulation and shock absorption, all protected by the durable inner and outer linerboards.

Decoding the Flute Profiles

Now, not all of those wavy layers are created equal. The size and spacing of these arches, known as the flute profile, are what determine the roll's specific characteristics. Each profile offers a different blend of cushioning, sturdiness, and surface smoothness.

Getting your head around these profiles helps you match the right roll to your exact needs, whether you're protecting delicate ceramics or wrapping bulky furniture.

Key Takeaway: Choosing the right flute profile is like picking the right suspension for a vehicle. A sports car needs a firm ride for performance, while a lorry needs heavy-duty suspension for big loads. In the same way, your items need the right corrugated 'suspension' for the best possible protection.

To help you pick the right one, here’s a quick look at the most common flute profiles you’re likely to come across.

Common Flute Profiles at a Glance

This table breaks down the most common flute profiles, showing what makes each one unique and what it’s best used for.

| Flute Profile | Flutes per Metre | Thickness | Key Characteristics | Ideal For |

|---|---|---|---|---|

| B-Flute | 164 | ~3mm | Good crush resistance, smooth surface, versatile | General wrapping, void fill, protecting items with sharp corners |

| C-Flute | 138 | ~4mm | Excellent cushioning and stacking strength | Wrapping larger, more fragile items; house moves |

| E-Flute | 312 | ~1.5mm | Thin, rigid, and provides a very smooth surface | Wrapping smaller products, interleaving, e-commerce retail packaging |

As you can see, a B-flute is a fantastic all-rounder, C-flute is your go-to for serious cushioning, and the finer E-flute is perfect when you need a smooth, rigid finish for smaller items.

Single Wall vs Double Wall Construction

The flute profile is just one part of the story. The number of layers also plays a huge part in the material's overall strength and durability. Most corrugated cardboard rolls you’ll find are single wall, which means one layer of fluting is sandwiched between two linerboards. This is perfect for most everyday wrapping and protection jobs.

For tasks that demand even greater protection, you can find materials with a double wall construction. This involves two layers of fluting and three linerboards, creating a much tougher and more rigid barrier. While it's less common in a roll format, this principle is crucial in the world of packaging. If you need maximum stacking strength for heavy items, you can explore the benefits of double wall boxes in our dedicated guide.

Everyday Applications for Corrugated Rolls

This is where the theory ends and the real work begins. Beyond all the talk of flute profiles and linerboards, the true magic of corrugated cardboard rolls lies in how incredibly useful they are in the real world. A simple roll of paper suddenly becomes your go-to tool for protecting, packaging, and preserving all sorts of items.

Its sheer adaptability makes it a staple for everyone from tradespeople to online sellers. For a decorator, it's a temporary shield for a client's prized wooden floor. For a growing online gift shop, it's a way to create bespoke packaging without splashing out on custom-made boxes.

For Movers and Homeowners

When you're moving house, protecting your furniture and valuables is everything. Corrugated rolls are a mover’s secret weapon, offering a tough yet flexible solution for safeguarding everything from an antique dresser to a modern glass coffee table.

If you’re planning a move, it's always worth checking out some good tips on moving house packing to see how the pros use materials like this to get the best results.

- Wrapping Large Furniture: A roll lets you create a seamless, cushioned skin around bulky things like sofas and wardrobes, protecting them from scratches and scuffs in the back of the removal van.

- Protecting Delicate Surfaces: You can easily wrap mirrors, big picture frames, and glass panels, making sure their fragile surfaces are shielded from knocks and bumps.

- Floor and Bannister Guarding: During the chaos of moving day, laying down corrugated cardboard creates a protective walkway. This simple trick prevents damage to floors, tiles, and carpets from heavy foot traffic and the odd dropped item.

This flexibility is a huge advantage over standard boxes, which simply can't handle the awkward shapes of most household furniture.

For E-commerce and Retail

In the competitive world of e-commerce, making sure your products arrive in one piece is non-negotiable. Corrugated cardboard rolls give small and medium-sized businesses an affordable way to ship oddly shaped items safely and professionally.

Imagine a small online store selling handmade pottery. They can cut and wrap each unique piece perfectly, avoiding the need to stock a massive inventory of different-sized boxes. It saves a huge amount of space and money.

The unstoppable rise of e-commerce is a major driver for new packaging ideas. The UK corrugated board packaging market is projected to hit USD 12.13 billion in 2025, expanding at a robust 3.9% compound annual growth rate, partly due to this relentless demand for reliable shipping materials.

Corrugated rolls empower businesses to create a custom packaging solution for any product, on demand. This eliminates the waste and expense of trying to make standard boxes fit non-standard items.

For Storage and Industrial Use

In warehouses and self-storage units, corrugated rolls serve a different but equally important purpose. They act as a brilliant separation and stabilisation tool.

- Interleaving and Layering: When stacking items, a sheet cut from a roll can be placed between layers. This simple practice, known as interleaving, stops items from scratching or sticking to each other over time.

- Pallet Lining: Before loading a pallet, laying down a layer of corrugated cardboard protects the bottom layer of goods from moisture and dirt from the pallet itself. For smaller, delicate items, you might find that combining the roll with some packing paper for wrapping offers an extra layer of defence.

How to Choose the Perfect Corrugated Roll

Choosing the right corrugated cardboard roll isn’t just a minor detail, it’s a critical decision that directly affects the safety of your items, your budget, and how much waste you produce. Get it wrong, and you’re looking at damaged goods or needless costs. This practical guide cuts through the confusion, helping you pick the perfect roll with confidence.

Making the right call means balancing four key factors: the weight and fragility of your items, the width of the roll, the total length you'll need, and the flute profile that gives you the right level of protection. By thinking through these elements, you can make sure your goods are perfectly protected every single time.

Evaluate Item Weight and Fragility

The first step, always, is to look at what you’re trying to protect. For lightweight, durable things like books or plastic goods, a standard B-flute single-wall roll is usually more than enough. Its good crush resistance provides an excellent protective skin against scratches and minor knocks.

However, for heavier or more delicate items, think antique mirrors, glass tabletops, or sensitive electronic equipment, you absolutely need to step up the protection. A thicker C-flute roll offers far superior cushioning, absorbing more shock during transit and handling. Those deeper flutes create larger air pockets, providing a much more robust buffer against bumps.

Select the Right Roll Width

Picking the correct width is essential for cutting down on waste and speeding up your packing process. Measure the largest dimension of the item you need to wrap. The goal is to choose a roll width that’s just slightly larger than this measurement, allowing for a small, neat overlap when you wrap.

Pro Tip: Using a roll that’s too narrow forces you to use multiple strips, creating seams that are natural weak points. On the other hand, a roll that’s too wide just leads to excessive trimming and wasted material. A well-chosen width ensures a clean, efficient wrap with minimal offcuts.

Calculate the Length You Need

Corrugated cardboard rolls are typically sold in long lengths, often 75 metres or more, which makes them very economical. To figure out how much you’ll need, just think about the scale of your project.

- For a single large item: Measure the perimeter and multiply it by the number of layers you want (usually two for decent protection).

- For moving house: A standard 75-metre roll is often enough to protect the major furniture items in a 2-3 bedroom house.

- For business use: Calculate your average weekly or monthly usage to work out how many rolls to order at once. This way, you’ll have enough stock without overcommitting your storage space.

Getting this right stops you from running out mid-task or buying far more than you need. When it comes to securing larger palletised loads, complementing your corrugated roll with the right pallet wrap and strapping is the key to total stability. This combination ensures everything from individual items to entire shipments stays put.

Why Corrugated Cardboard Is a Sustainable Choice

In a world where every choice we make has an environmental footprint, your packaging materials matter more than ever. Opting for corrugated cardboard rolls isn't just a practical decision; it's a powerful statement about sustainability. This isn't just a packaging material; it’s a key player in the circular economy, designed from the ground up to be reused, recycled, and repurposed, minimising its impact on the planet.

Unlike single-use plastics that can hang around in landfills for centuries, corrugated cardboard is born from renewable resources, primarily wood pulp from sustainably managed forests. Better yet, many rolls already contain a high percentage of recycled fibres, meaning they’ve lived previous lives as boxes or other paper products. It's this cycle of use and reuse that makes it such a responsible choice.

The Impressive Recycling Journey

The story of corrugated cardboard doesn't end when your package is delivered. In fact, that’s just the beginning of its next chapter. Its seriously impressive recyclability rate is a real testament to its sustainable design.

Each year, UK businesses and households generate a massive 5,389,000 tonnes of paper and cardboard packaging waste. Within this, corrugated materials boast a fantastic 70.6% recycling rate, with a staggering 3,802,000 tonnes being repurposed. This remarkable effort saves the equivalent of 34 million trees every single year.

Choosing corrugated cardboard isn't just about protecting your products. It's an active participation in a successful, large-scale recycling system that conserves natural resources and cuts down on landfill waste.

How to Recycle Your Rolls Correctly

To make sure your used corrugated cardboard rolls can be efficiently recycled, a little bit of prep work goes a very long way. Following these simple steps ensures the fibres stay in top condition for their next life:

- Remove All Tape: Plastic packing tape is a major headache in the paper recycling process, so peel off as much of it as you can.

- Keep It Dry: Wet or greasy cardboard simply can't be recycled. Keep your used rolls somewhere dry until collection day.

- Flatten Everything: Flattening rolls or any boxes you've made saves a huge amount of space in your recycling bin and makes transport far more efficient for the collection crews.

By making smart, sustainable choices, we all contribute to a healthier planet. Understanding how different materials affect our world is key, and to get a deeper perspective on recycling's role, you can explore the broader environmental impact of waste and see how other industries are tackling these challenges.

And if you're on the hunt for other eco-friendly packaging, you might be interested in our guide to https://www.theboxwarehouse.co.uk/bio-degradable-bubblewrap.html.

Smart Buying Strategies for Trade and Bulk Orders

For any business where packaging is a daily operational cost, smart purchasing isn't just a good idea, it's essential for keeping your profit margins healthy. If you’re a removal company, an e-commerce seller, or a manufacturer, buying corrugated cardboard rolls in bulk is hands down the most effective way to manage these expenses.

Moving from single-roll purchases to a wholesale or trade account is where you’ll see the real difference. Suppliers almost always offer a much lower price per metre on larger orders, which quickly adds up to serious savings over a financial quarter. This simple switch turns a fluctuating expense into a predictable, manageable budget item, making your financial forecasting a whole lot easier.

Planning for Lead Times and Supply

When you start buying in bulk, a bit of forward-thinking becomes crucial. While many suppliers can get standard stock out for next-day delivery, bigger or custom orders will naturally need a longer lead time. To avoid the nightmare of a critical shortage that could grind your operations to a halt, it's vital to get a reliable ordering cycle sorted with your supplier.

Building a strong partnership with a packaging provider like The Box Warehouse means you can count on a consistent supply chain. A good relationship like this often unlocks better pricing and priority service, and you get expert advice on the most cost-effective solutions for your specific needs, like choosing the perfect flute profile for your products.

For any high-volume business, the goal is to treat packaging not as an afterthought, but as a core part of your inventory management. Running out of corrugated rolls should be as unthinkable as running out of your primary product.

Storing Bulk Rolls Correctly

Buying in bulk only pays off if the material stays in perfect condition until you need it. Storing it incorrectly can ruin your investment in a flash.

- Keep Them Dry: Moisture is the absolute enemy of cardboard. Make sure you store your corrugated rolls in a dry, cool area, well away from any damp walls or floors.

- Store Off the Ground: Use pallets or shelving to keep the rolls elevated. This protects them from ground-level moisture and any potential pests.

- Avoid Direct Sunlight: Long-term exposure to UV rays can weaken the paper fibres over time, making the material less effective at protecting your goods.

The UK's corrugated paper market is a massive industry, recently valued at $749 million with a staggering 420,000 tons consumed. These numbers show just how deeply businesses rely on materials like corrugated cardboard rolls. You can get a closer look at the UK corrugated paper market trends and analysis on indexbox.io.

Common Questions About Corrugated Rolls

Even with a good grasp of the basics, a few questions always pop up. It’s totally normal. Think of this as your go-to guide for those final queries, whether you're about to pack up your house or sort out your e-commerce shipping.

Is Corrugated Cardboard the Same as Regular Cardboard?

Not at all – they’re two completely different materials designed for very different jobs. What most of us call ‘regular cardboard’ is actually paperboard. It’s a single, flat layer of paper pulp, the stuff used to make cereal boxes or greetings cards.

Corrugated cardboard, on the other hand, is a much cleverer and more complex structure. It has a wavy, fluted layer sandwiched securely between two flat sheets of linerboard. This three-layer construction gives it a huge advantage in strength and cushioning, making it the only real choice for protecting things during a move or in transit. That wavy fluting is where the protective magic happens.

Can I Use Corrugated Rolls to Protect Floors?

Absolutely. In fact, it's a brilliant and very cost-effective way to protect floors during a renovation, redecoration, or house move. That cushioned structure is a fantastic shield for hardwood, tiles, and carpets, protecting them from scratches, dents, and dirt from heavy foot traffic or dropped tools.

Just roll it out to create a tough, temporary walkway. The material is durable enough to take a beating but light enough to be positioned and removed in minutes once you’re done, leaving your floors looking perfect.

Top Tip: For the best protection on hard floors, always lay the fluted (wavy) side facing down. This leaves the smooth, flat surface facing up, giving you a much more stable and even path to walk on.

At The Box Warehouse, we stock high-quality corrugated cardboard rolls and all the other packaging essentials you need for moving, shipping, or storage. You can explore our full range of protective solutions today at https://www.theboxwarehouse.co.uk.