Published on : 03 January 2026

A Complete Guide to Choosing the Right Rolls of Foam

That heart-stopping moment when you’re about to pack a treasured heirloom or a brand-new telly is something we all know. You need something more dependable than old t-shirts, which is exactly where rolls of foam come in. This versatile material is the professional’s choice for cushioning valuables against knocks, scratches, and vibrations on the move.

Why Foam Rolls Are Your Packaging Secret Weapon

Think of foam wrap as a protective second skin for everything you care about. From delicate glassware and polished furniture to sensitive electronics, its lightweight and non-abrasive qualities make it an essential tool for ensuring items arrive in mint condition.

Whether you're moving house, running an e-commerce business, or managing a removals company, knowing how to use foam wrap properly is a game-changer. This guide is here to walk you through everything, from picking the right type to mastering professional packing techniques.

A Growing Need for Protection

The demand for reliable protective packaging is definitely on the rise, driven by the unstoppable growth of online shopping and the complex journeys goods now take to reach our doors. This trend puts the spotlight firmly on materials that can genuinely safeguard products.

The United Kingdom's foam packaging inserts market is projected to expand at a compound annual growth rate (CAGR) of 6.8% between 2025 and 2035. This steady growth shows just how much we're relying on dependable protective solutions across countless industries.

This isn't just a niche market; it shows how vital materials like foam rolls have become for businesses and regular households alike.

More Than Just Foam

Here's a pro tip: great packing is rarely about just one material. While foam rolls are brilliant for surface protection and light cushioning, they work best as part of a team.

After carefully wrapping an item in foam, it’s vital to place it inside a sturdy container. Combining soft foam wrap with high-quality cardboard boxes creates a robust, two-layer defence system. The foam guards against scratches, while the box protects against crushing forces.

This simple combination ensures your items are fully shielded from all the typical hazards of moving, shipping, or storage. Our goal is to give you the knowledge to pack with total confidence.

Decoding the Different Types of Foam Rolls

Stepping into the world of packaging can feel a little overwhelming, especially when you’re faced with a wall of different rolls of foam. But don't get bogged down in technical jargon. Think of choosing foam like picking the right tool for a specific job; each type has unique strengths designed for different protection tasks.

Not all foam is created equal. The material it's made from dictates its flexibility, cushioning power, and suitability for certain items. Getting your head around these core differences is the first step towards packing like a pro and ensuring your valuables are properly shielded.

Making the right choice means your delicate glassware won’t rattle, your wooden furniture won’t get scratched, and your sensitive electronics will be safe from static. Let's break down the main players you’ll come across.

Polyethylene Foam: The Versatile All-Rounder

Polyethylene (PE) foam is the most common type you'll see, and for good reason. Imagine it as the reliable 'all-rounder' of the packaging world. It’s lightweight, surprisingly strong, and has a closed-cell structure, which is a fancy way of saying it doesn’t absorb water.

This makes it perfect for a huge range of jobs. Its primary mission is to prevent surface damage like scratches, scuffs, and minor dings. It's the ideal material for wrapping everyday items that need a gentle, non-abrasive layer of protection.

Here’s where you’ll find PE foam most useful:

- Interleaving Plates: Placing a sheet between each dish stops them from clattering and chipping during a move.

- Wrapping Picture Frames: Protects both the glass and the frame from scratches in transit.

- Guarding Furniture Surfaces: A layer over a polished wooden table or cabinet door is a simple way to prevent surface marks.

Its sheer versatility has made it a cornerstone of the packaging industry. The market for packaging foams in the UK was valued at USD 1.43 billion in the current year and is expected to grow significantly. This growth is largely driven by materials like polyethylene, which just goes to show its dominance in both commercial and domestic settings.

Polyurethane Foam: The Custom-Fit Cushion

If polyethylene is the all-rounder, then polyurethane (PU) foam is the specialist. Think of it as the 'memory foam' of packaging. It's much softer, spongier, and has an open-cell structure, which allows it to conform perfectly around irregularly shaped items.

PU foam excels at providing a custom-fit cushion for extremely delicate or valuable objects. It’s less about stopping surface scratches and more about absorbing shock and vibration, holding an item securely in place.

Pro Tip: Polyurethane foam is often used as convoluted 'egg box' style inserts inside cases for high-value equipment like cameras, musical instruments, or scientific tools, where a snug fit is absolutely essential.

This type of foam is your go-to when you need to completely immobilise a fragile object within a box, ensuring it doesn't shift an inch during its journey.

Specialty Foams for Specific Needs

Beyond the two main types, you’ll find a few specialty rolls of foam designed for very specific protective jobs. The most common of these is anti-static foam, which you can spot a mile off thanks to its signature pink colour.

Anti-static foam acts as a bodyguard for sensitive electronics. It's specially treated to safely dissipate electrostatic discharge (ESD), those tiny, invisible 'shocks' that can fry delicate components like motherboards, processors, and circuit boards. If you're shipping or storing computer parts or other sensitive electronics, using anti-static foam isn't just a good idea; it's essential.

To help you choose at a glance, this table breaks down which material is best for your particular job.

Foam Roll Material Selector

| Material Type | Key Characteristic | Best Used For | Example Items |

|---|---|---|---|

| Polyethylene (PE) Foam | Lightweight, non-abrasive, closed-cell (water-resistant). | General surface protection against scratches and scuffs. | Furniture, dishes, picture frames, mirrors, general housewares. |

| Polyurethane (PU) Foam | Soft, spongy, open-cell (conforms to shape). | Shock absorption and custom-fit cushioning for delicate items. | High-value electronics, scientific instruments, camera equipment, musical instruments. |

| Anti-Static Foam | Dissipates electrostatic discharge (ESD). Usually pink. | Protecting sensitive electronic components from static damage. | Computer motherboards, circuit boards, processors, hard drives. |

By understanding these key types, you can confidently select from the various foam roll options available and match the right material to your specific needs, ensuring complete protection every time.

Choosing the Right Foam Thickness and Density

Once you’ve settled on the best foam material for the job, the next big decision is thickness and density. Honestly, getting this part right is the difference between your items arriving in one piece and a potential disaster. Think of it as a two-part defence system for your valuables.

Thickness is your cushion. It’s all about how much of a knock the foam can soak up before the shock gets through to your item. Just like a thicker mattress gives you a comfier night's sleep by buffering you from the bed frame, a thicker foam roll provides a much better cushion against bumps and drops.

Density, on the other hand, is the shield. This is about how compact the material is, which gives it the muscle to resist punctures, compression, and heavy loads. A denser foam is like a firmer mattress, it offers more support and stops things from sinking in or getting crushed under pressure.

Matching Thickness to the Task

The thickness of rolls of foam is usually measured in millimetres (mm), and even a tiny difference can have a huge impact on the level of protection you get. Choosing the right thickness means you never waste money on material you don't need or, far worse, leave your precious items under-protected.

Let’s break down the most common thicknesses and what they’re actually good for in the real world:

- 1mm Foam: This is the thinnest option out there, designed almost exclusively for surface protection. It’s perfect for stopping light scratches, scuffs, and dust on things that aren't particularly fragile or heavy.

- 2.5mm Foam: A brilliant middle-ground option, this thickness gives you a good mix of surface protection and a bit of light cushioning. It’s a really versatile choice for separating stacked items or wrapping objects that need a little more padding than the 1mm foam can offer.

- 4mm Foam: When you need some more serious cushioning, 4mm is the one to go for. This thickness provides proper, substantial protection against impacts and is ideal for wrapping heavier, more fragile items that are at a greater risk during a move.

To make this even clearer, here are a few practical examples of what to pack with each thickness.

Example Scenarios

- Using 1mm Foam: Perfect for wrapping television screens, the glass in picture frames, or placing between the glossy covers of books to prevent scuffing.

- Using 2.5mm Foam: The ideal choice for putting between a stack of dinner plates, wrapping delicate ornaments, or protecting the corners of small bits of furniture.

- Using 4mm Foam: Your best bet for cushioning heavy ceramic pots, wrapping large vases, or giving extra protection to electronics like printers or monitors.

Understanding Foam Density

While thickness is pretty easy to get your head around, density can feel a bit more abstract. In simple terms, a low-density foam is light and airy, and it squashes easily. A high-density foam is much firmer and more resistant to being compressed.

Most of the general-purpose polyethylene foam rolls you'll come across have a standard, low-to-medium density, which is spot-on for the vast majority of moving and shipping jobs. This standard density offers excellent flexibility and cushioning without adding loads of unnecessary weight to your packages.

The key takeaway here is that for most household moves and general shipping, you’ll be perfectly well-served by standard-density foam. High-density options are usually reserved for specialised industrial jobs, like protecting extremely heavy machine parts or providing long-term structural support inside a crate.

For more complex packing challenges, like protecting items with very sharp or protruding edges, you might want to look at more specialised solutions. Alongside standard rolls, consider options like custom foam profile protection, which can be fitted directly onto edges and corners for a targeted, high-density defence.

By carefully thinking about both the 'cushion' of the thickness and the 'shield' of the density, you can create a tailored protection strategy for every single thing you pack. This thoughtful approach ensures that everything, from your thinnest wine glass to your heaviest piece of art, arrives at its destination in perfect condition, giving you complete peace of mind.

Putting Foam Rolls to Work in the Real World

Knowing the theory behind foam types is one thing, but getting it right in practice is what will actually keep your stuff safe. Let’s move from the 'what' to the 'how' and look at using rolls of foam in three common situations. Each one needs a slightly different approach, but the goal is always the same: making sure everything arrives in perfect condition.

Whether you're packing up your life for a house move, sending products to customers, or tucking cherished items away into long-term storage, mastering a few key techniques makes all the difference. We’ll cover the step-by-step methods the pros use every day to protect valuables from the inevitable bumps and scrapes of being on the move.

And make no mistake, the need for this kind of protection is booming. The flexible foam packaging market is on track to hit US$8.7 billion in 2026, with projections climbing to US$12.4 billion by 2033. This growth is being fired up by the massive expansion of e-commerce and the constant search for lighter, more efficient packaging.

Best Practices for Moving House

Moving house is stressful enough without having to worry about your belongings. Proper packing takes a huge amount of that anxiety away, and foam rolls are a non-negotiable part of any decent ultimate moving house packing checklist.

Here are a few pro techniques for common household items:

- Wrapping Dinner Plates: Lay a sheet of 2.5mm foam on a flat surface. Pop the first plate in the centre, cover it with another sheet of foam, and stack the next plate on top. Repeat for 4-5 plates, then wrap the entire stack securely in a final, larger sheet.

- Protecting Framed Art: For pictures or mirrors, grab some 2.5mm or 4mm foam. Wrap the whole frame like you’re wrapping a gift, paying extra attention to the corners, that's where damage is most likely to happen.

- Securing Furniture: For big items like tables or chests of drawers, roll out a long section of 4mm foam to cover the entire surface. This stops other items from scratching against it in the removal lorry. Combining foam wrap with specialised corner protectors is a really smart move; our complete furniture protection kits for a comprehensive solution have you covered.

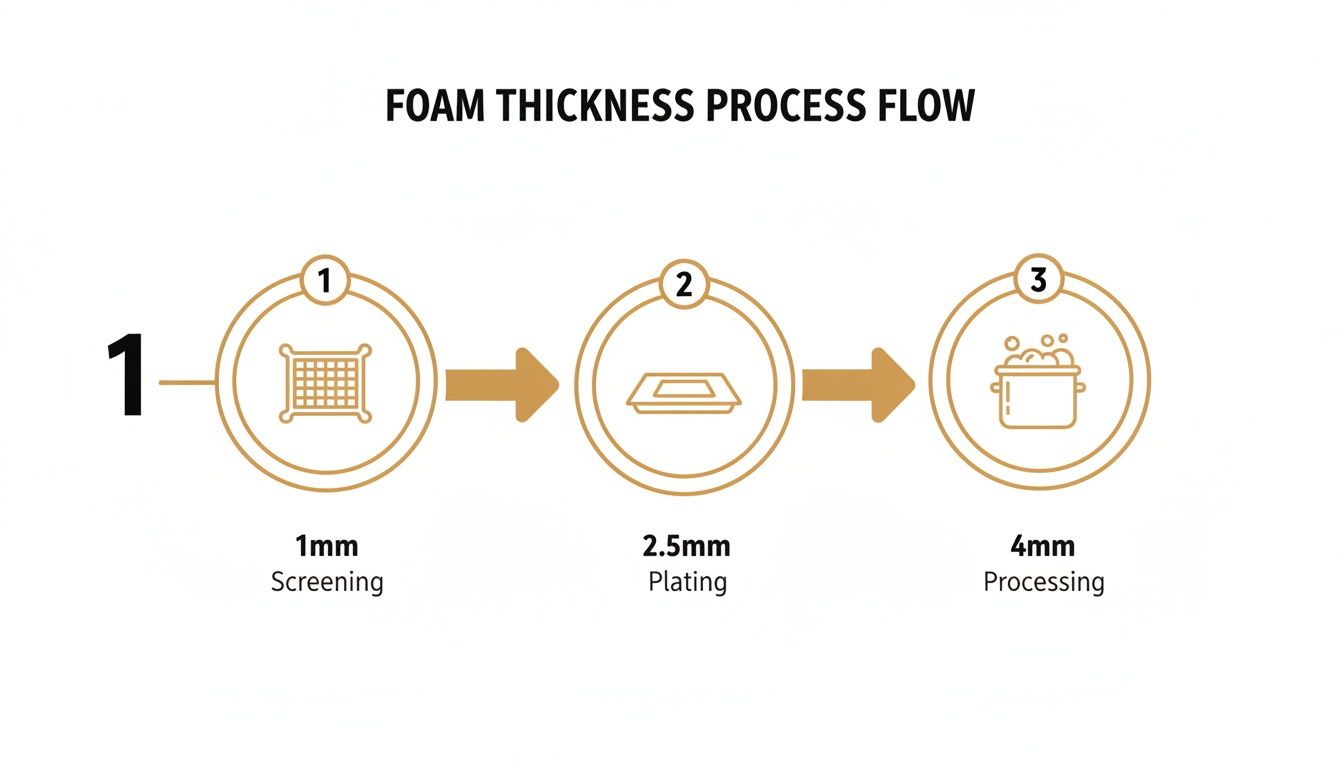

This quick visual guide shows how foam thickness lines up with different protection needs.

It’s a simple concept: thinner foam is for scratch prevention, while the thicker stuff provides real impact cushioning for heavier, more vulnerable items.

Professional Tips for E-Commerce Shipping

For an e-commerce business, the "unboxing experience" is a massive part of customer satisfaction. Using foam wrap doesn’t just protect your products; it sends a clear message to the customer that you care about quality.

A well-packaged item feels professional and secure.

Pro Tip: Cut your foam to size before you start packing a batch of orders. Having a stack of pre-cut sheets ready to go streamlines the whole process, saving you valuable time during busy periods and ensuring a consistent, tidy look for every parcel.

Here’s a simple process for a secure, professional package:

- First Layer: Wrap the product snugly in a layer of 1mm or 2.5mm foam. This is your first line of defence against surface scuffs and moisture.

- Secure with Tape: Use a small bit of packing tape to hold the foam in place. This stops it from unravelling as you place it in the box.

- Fill the Voids: Pop the foam-wrapped item inside your shipping box. Use extra packing materials like bubble wrap or packing paper to fill any empty space, stopping the item from rattling around.

Guarding Valuables in Long-Term Storage

When you're putting things into storage, your main enemies are moisture, dust, and the constant pressure from stacked boxes. Foam rolls are an excellent line of defence here. Because polyethylene foam has a closed-cell structure, it doesn’t absorb water, which makes it a really effective moisture barrier.

For long-term protection, think total coverage.

- The Mummy Wrap: For items like chair or table legs, wrap each one on its own before wrapping them all together. This "mummy wrap" technique stops them from knocking against each other and prevents pressure points from forming over time.

- Cover and Seal: For wooden furniture or electronics, cover the whole item with a generous layer of 4mm foam. Make sure every surface is covered before you place it inside a sealed protective bag or under a dust sheet. This helps guard against the humidity and temperature swings you often get in a storage unit.

Foam Rolls vs Bubble Wrap: When to Use Each

It’s the classic packaging dilemma, a choice faced in warehouses and living rooms all over the UK. Foam roll or bubble wrap? But instead of trying to crown one clear winner, it’s much more helpful to see them as specialised tools, each with its own distinct job.

Getting this choice right is the key to giving your items the exact protection they need, without over-packing or leaving them vulnerable.

Think of it like this: rolls of foam are a ‘protective skin’. Their main purpose is to defend against surface-level damage, think scratches, scuffs, moisture, and the minor friction that happens in transit. The soft, non-abrasive texture makes it the perfect first layer for anything with a delicate finish.

Bubble wrap, on the other hand, is an ‘airbag system’. Each of those little pockets of air is designed to absorb sharp impacts and cushion your items against drops. It’s your go-to for shock absorption and for filling empty space in a box to stop things from rattling around.

Head to Head Comparison

To make the decision a bit simpler, let’s break down their core strengths and weaknesses. Understanding these key differences will help you match the right material to the job every single time, avoiding costly damage and wasted materials. This isn’t about which one is better overall, but which is better for the specific task you’re facing right now.

Here’s a quick head-to-head that lays it all out.

Foam Roll vs Bubble Wrap Head-to-Head

| Feature | Rolls of Foam | Bubble Wrap |

|---|---|---|

| Primary Function | Surface protection (scratches, scuffs, moisture). | Impact and shock absorption. |

| Best For | Polished furniture, glass screens, leather goods, artwork. | Hollow or irregularly shaped items like vases, ceramics, mugs. |

| Flexibility | Highly flexible, easily conforms to flat surfaces and shapes. | Less flexible, can be bulky around corners and flat items. |

| Moisture Resistance | Excellent, closed-cell structure creates a reliable moisture barrier. | Good, but moisture can get trapped between the bubbles. |

| Cost | Generally more cost-effective for covering large surface areas. | Can be more expensive per square metre, especially for larger bubbles. |

As you can see, their strengths are almost perfect opposites. Where one excels, the other often falls short, which is exactly why having both on hand is a smart strategy for any serious packer.

Making the Right Choice Every Time

So, when should you reach for the foam, and when is it bubble wrap’s time to shine? Let’s look at a few real-world examples to make it crystal clear.

- For a polished wooden tabletop: Foam roll is the only answer. Its soft surface won't leave imprints or scratch the delicate finish, providing a perfect shield against friction.

- For a hollow ceramic vase: Bubble wrap is the superior choice here. It will cushion the vase against knocks and can be used to fill the interior, providing structural support from the inside out.

- For a flat-screen TV: Use both. Start with a layer of 1mm foam wrap directly against the screen to prevent scratches, then add an outer layer of bubble wrap for impact protection during transit.

This layered approach, combining the surface protection of foam with the shock absorption of bubble wrap, offers the ultimate defence for high-value items. It’s a technique professional removal companies use daily.

By understanding the unique roles of each material, you can pack far more efficiently and with greater confidence. To see how bubble wrap can complement your foam rolls, you can explore the various types of bubble wrap available and their specific applications.

How Much Foam Do You Actually Need?

Nothing kills your packing momentum faster than running out of supplies halfway through, just as you’re hitting your stride. On the other hand, overbuying rolls of foam is a costly mistake that leaves you with stacks of material you don't need. A little bit of planning is all it takes to sidestep both problems and get the quantity just right.

Figuring out how much you need doesn’t have to be some complex mathematical equation. For most jobs, a few simple rules of thumb will get you incredibly close to the perfect amount, whether you’re wrapping a few heirlooms or packing up an entire house. This practical approach saves you time, money, and a whole lot of last-minute stress.

Let's walk through a couple of easy methods for estimating how much foam to order, one for moving house and another for businesses.

A Simple Rule for Home Movers

If you’re moving house, the easiest way to estimate your foam needs is to base it on the size of your property. It’s a reliable shortcut used by professional removal companies to quickly scope out a job. While every home is different, this guideline gives you a fantastic starting point for your shopping list.

A good, dependable rule of thumb is:

For an average three-bedroom house move, you should plan for approximately two 100-metre rolls of foam. This amount is usually enough to protect large furniture surfaces, wrap delicate kitchenware, and keep your mirrors and framed art safe.

For a smaller place, like a one or two-bedroom flat, a single 100-metre roll will often do the trick. If you’re in a larger property or have a serious collection of fragile items, think antiques or a lot of glassware, it’s always smart to add an extra roll just to be on the safe side.

Smart Calculations for Businesses

For businesses, calculating your foam needs is less about a single project and more about making your day-to-day operations as smooth as possible. Whether you're running a removals firm or an e-commerce store, efficiency and cost are everything.

For Removal and E-commerce Companies

The key here is to look at your typical workflow. Think about these points to fine-tune your buying strategy:

- Roll Width: What are you usually wrapping? Large, flat surfaces like tabletops are much easier to cover with a wider roll (say, 1500mm). For smaller, individual products going into boxes, a narrower roll (like 500mm) is far more manageable and creates less waste.

- Bulk Buying: Ordering rolls of foam in bulk nearly always brings the cost per metre right down. This doesn't just save you money; it also means you've always got stock on hand, preventing those annoying delays that happen when you run out of supplies unexpectedly.

- Workflow Optimisation: The right roll dimensions can directly boost your team's productivity. A roll that’s too wide or too narrow for your main packing tasks will only slow people down and create more offcuts. Take a look at your most common jobs and standardise the roll sizes you buy to match them perfectly.

Common Questions About Using Rolls of Foam

Even with the best guide in the world, you're bound to have a few questions when you're using a product for the first time. It’s totally normal. To help you pack with complete confidence, we’ve pulled together the queries we hear most often from our customers about rolls of foam.

Think of this as your quick-reference troubleshooter. We’ve kept the answers clear and straightforward so you have all the information you need, right when you need it.

Are Rolls of Foam Recyclable in the UK?

This is a fantastic question and one that's rightly on a lot of people's minds. The good news is that most foam wrap is made from Low-Density Polyethylene (LDPE), which carries the number 4 recycling symbol.

However, it’s not quite as simple as just tossing it in your household recycling bin. Most local councils don't accept plastic films like foam wrap in their kerbside collections because they can clog up the sorting machinery.

Instead, you can usually recycle it in a couple of other ways:

- Supermarket Collection Points: Many larger supermarkets now have collection bins for flexible plastics and carrier bags. LDPE foam is often accepted in these.

- Local Recycling Centres: Your nearest household waste recycling centre will almost always have a specific container for plastic films.

For businesses dealing with larger amounts, commercial waste services often provide dedicated collections for LDPE. The golden rule is to always have a quick check of your local council's specific guidelines to be sure.

Can I Use Foam Wrap to Protect Items From Moisture?

Absolutely. In fact, this is one of the standout benefits of using polyethylene foam. The material is what’s known as 'closed-cell,' which is just a technical way of saying it’s non-absorbent. It acts as a brilliant barrier against moisture, humidity, and even mildew.

This quality makes rolls of foam an excellent choice for protecting items in long-term storage, especially in places where temperatures can fluctuate, like garages, lofts, or self-storage units. It provides a reliable shield against the kind of damp that can damage wood, electronics, and fabrics over time.

What Is the Best Way to Cut Foam From a Roll?

Getting a clean, straight cut not only makes your packing look more professional but is also much easier to work with. For the best results, roll the foam out on a flat, protected surface, a cutting mat or a large piece of scrap cardboard is perfect.

You can use either a sharp craft knife or a large, sharp pair of scissors. A dull blade is your enemy here; it will snag and tear the foam, leaving you with a messy, uneven edge. If you're using a craft knife, lay a ruler or another straight edge along your desired line and use it as a guide. You'll get a perfectly straight cut every time.

Is Foam Wrap Safe for Protecting Wooden Furniture?

Yes, foam wrap is arguably one of the safest materials you can use for delicate surfaces. Its soft, non-abrasive texture is specifically designed to prevent scratches, scuffs, and marks on things like polished wood, lacquered finishes, and veneers.

What’s more, polyethylene foam is chemically inert. This means it won't react with varnishes or finishes, making it ideal for both short-term moving and the long-term storage of valuable or antique furniture. You can wrap your items with complete peace of mind, knowing the surface underneath is fully protected.

At The Box Warehouse, we provide everything you need to pack like a professional, from high-quality foam rolls to sturdy cardboard boxes. Explore our complete range of packaging supplies today.

Find the perfect packaging solution at https://www.theboxwarehouse.co.uk.