Published on : 26 November 2025

Your Essential Guide to Shipping Cardboard Boxes

Choosing the right shipping cardboard boxes really just boils down to one thing: matching the box to your item's weight, size, and fragility. Lighter, tougher goods will probably be fine in a single-wall box. But for anything heavier or more delicate, you’ll want the beefed-up protection of a double-wall box. Getting this right is the first and most important step to making sure your products arrive in one piece without costing you a fortune.

Why Your Box Choice Is the Foundation of Safe Shipping

Think of your shipping box as a suit of armour for whatever you’re sending. Just like armour needs to be strong enough for the journey and fit properly, so does your box. A flimsy or ill-fitting box is just asking for trouble – it’s a fast track to damaged goods, unhappy customers, and costs you definitely didn't budget for.

This decision has never been more important, especially in the UK's booming e-commerce scene. The UK's corrugated packaging market has exploded, hitting a value of £11.67 billion in 2024. That number is set to grow by another 3.90% every year until 2029, all thanks to the sheer volume of parcels zipping around the country. More parcels mean more chances for things to go wrong, making reliable packaging absolutely essential.

The Core Principles of Box Selection

Picking the right box isn’t guesswork. It's about striking a smart balance between protection and cost. Before we get into the nitty-gritty of flute types and board grades, let's nail down the basics that should guide every choice you make. The goal is simple: create a safe, secure bubble for your product from the moment it leaves you to the moment it’s unboxed.

Here are the key things you need to think about:

- Product Weight: The heavier the item, the more stress it puts on the box. You’ll need stronger walls to stop it from collapsing under its own weight.

- Item Fragility: Delicate things like ceramics, glass, or electronics need a box that can take a hit and absorb shocks without caving in.

- The Journey: A parcel travelling across the country with multiple courier handovers will face a lot more bumps and scrapes than one going a few miles down the road.

- Cost: While you can’t skimp on protection, using a box that’s too big or over-engineered is just a waste of money on materials and shipping fees.

The best packaging strategy starts with the simplest element: the box itself. Get this right, and everything else—from void fill to sealing tape—becomes far more effective. A strong outer shell is your first and most important line of defence.

At the end of the day, the right box does more than just hold your items. It protects your investment, upholds your brand’s reputation, and makes sure your customer has a great experience. Once you understand these basics, you’re already on your way to mastering the art of safe and efficient shipping.

Understanding Box Anatomy and Strength

To pick the right shipping cardboard boxes, you first need to get to grips with what makes one stronger than another. It’s not just about how thick it feels; the real secret lies in its internal structure. Think of it like a house – the design of the walls determines how well it stands up to pressure, not just the thickness of the plaster.

The same idea applies to your packaging. A simple piece of folded card is fine for a birthday greeting, but it won’t do much to protect a set of ceramic mugs on a journey across the country. That's where the clever construction of corrugated cardboard comes in, turning a basic container into a durable shield for your products.

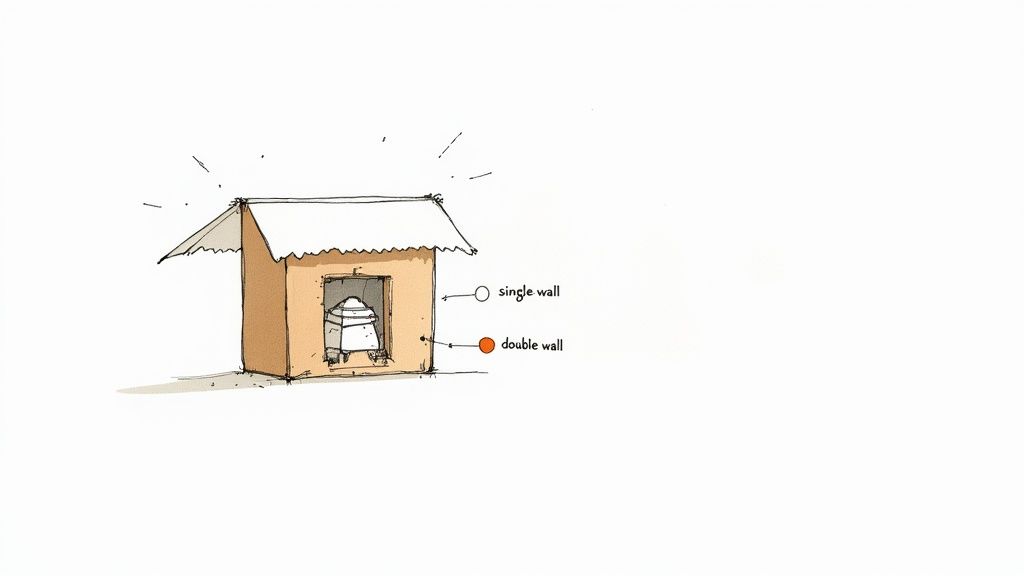

Single Wall vs Double Wall Boxes

The most fundamental difference in box strength comes down to its wall construction. This is the first decision you'll make, and it’s a big one.

Single-Wall Boxes: These are your everyday workhorses. They have two flat outer layers of paper (liners) with a single, wavy layer of corrugated paper squashed between them. This design offers a great balance of sturdiness and cushioning for items that aren't excessively heavy or fragile.

Double-Wall Boxes: When you’re shipping heavier or more delicate items, you need to bring in the reinforcements. A double-wall box adds an extra layer of corrugated paper and another liner, creating a much tougher five-layer structure. It's like adding an extra internal wall to that house – the result is significantly stronger, more rigid, and far more resistant to being crushed or punctured. That extra strength is essential for stacking boxes in a warehouse or van.

Choosing between them is a simple calculation of risk versus cost. A single-wall box might save you a few pence, but a double-wall box delivers peace of mind, protecting your valuable goods from the inevitable bumps and scrapes of the delivery network.

The Secret to Box Strength: The Flute

While the number of walls is important, the unsung hero of a cardboard box's strength is the corrugated flute. This is the wavy, arched layer of paper tucked between the flat liners. These arches are what give the box its rigidity and cushioning, acting like a series of tiny, supportive columns.

Just as an architect uses arches to support a bridge, the flutes in a box distribute pressure across a wider area. Without this clever design, a box would just be a flimsy paper folder. If you're curious about the raw materials, you can learn more about what cardboard is made of in our detailed guide.

The flute is the backbone of the box. Its size and shape directly influence the box's ability to resist crushing, absorb impacts, and even how well you can print on its surface.

Common Flute Types and Their Uses

You don’t need to be an engineer to get your head around flutes. Just remember that different letters correspond to different sizes and strengths. Here are the most common ones you'll run into when choosing your shipping cardboard boxes.

B Flute: At around 3mm thick, this is a fantastic all-rounder. It gives you good crush resistance and has a smooth surface that’s great for printing. It’s a hugely popular choice for everything from subscription boxes to shipping tins of food.

C Flute: A bit chunkier at around 4mm, this is the industry standard for general shipping boxes. It provides excellent crush resistance and solid stacking strength, making it perfect for packing heavier things like books, small appliances, and household goods.

E Flute: This one’s much thinner, only about 1.5mm thick. While it’s not the best for heavy-duty shipping, its slim profile and super-smooth surface make it ideal for retail packaging like pizza boxes or cosmetic cartons where presentation is everything.

When you see a double-wall box, it often uses a combination of flutes to get the best of both worlds. For instance, a BC Flute combines a B flute and a C flute, offering a superb blend of cushioning and structural integrity. This combination is the go-to for heavy-duty shipping, providing robust protection you can really rely on.

How to Measure and Match Boxes to Your Products

Getting the right shipping box is more than just finding one that fits – it's about protecting your products and your bottom line. Pick a box that’s too big, and you're just paying to ship air and wasting money on void fill. Go too small, and you're risking damage with almost zero protection. The goal is to find that perfect, snug fit that keeps items secure from door to door.

This has never been more important. With UK e-commerce booming, couriers are expected to handle a massive 1.29 billion shipments between October and December 2024 alone. That's a 10.9% jump from last year, putting immense pressure on every single package to survive the journey.

Step 1: Measure Your Product Accurately

First things first, you need the exact dimensions of your item. Grab a tape measure and note down the length, width, and height at their very widest points. It's always a good idea to round up to the nearest centimetre, just to be safe.

What about odd-shaped items, like a vase or sculpture? Simple. Imagine a tight, invisible box drawn around it. Measure that imaginary box – those dimensions are the minimum internal space you'll need. Getting this right is the foundation of a successful shipment.

Step 2: Add Your Protective Buffer

You never want your product rattling around or touching the inside walls of the box. That’s where your protective cushion comes in. You need to leave a little extra room on all sides for packing materials like bubble wrap or packing paper.

As a rule of thumb, add 5cm (about 2 inches) to each of your product's dimensions.

- Final Box Length = Item Length + 5cm

- Final Box Width = Item Width + 5cm

- Final Box Height = Item Height + 5cm

This buffer gives you enough space to wrap the item properly and stuff any gaps, stopping it from shifting or taking a direct hit during transit. For smaller items heading out with Royal Mail, it's worth checking out a range of purpose-built postal boxes that are designed for cost-effective mailing.

Step 3: Match Box Strength to Item Weight and Fragility

Once you have your dimensions sorted, the final piece of the puzzle is matching the box's strength to what's inside. This is where you'll decide between a single-wall or double-wall box.

Take a hardback book, for example. It's pretty tough and not especially heavy, making it a perfect candidate for a good quality single-wall box. The main job is to stop it getting scuffed up, which a well-fitted carton can handle with ease.

The most common shipping mistake is underestimating the stresses of transit. A box that feels strong enough in your hands may not withstand the pressure of being stacked under heavier parcels in a delivery van. Always err on the side of caution with fragile or heavy goods.

Now, think about something like a delicate ceramic mug. It's light, but incredibly fragile. Here, a double-wall box is a must. That second layer of corrugated board gives it far better crush resistance and shock absorption, creating a rigid shield to protect it from the inevitable bumps and drops.

Think of it like this:

By quickly categorising your product, you can confidently choose a box that gives you the right level of protection without overspending.

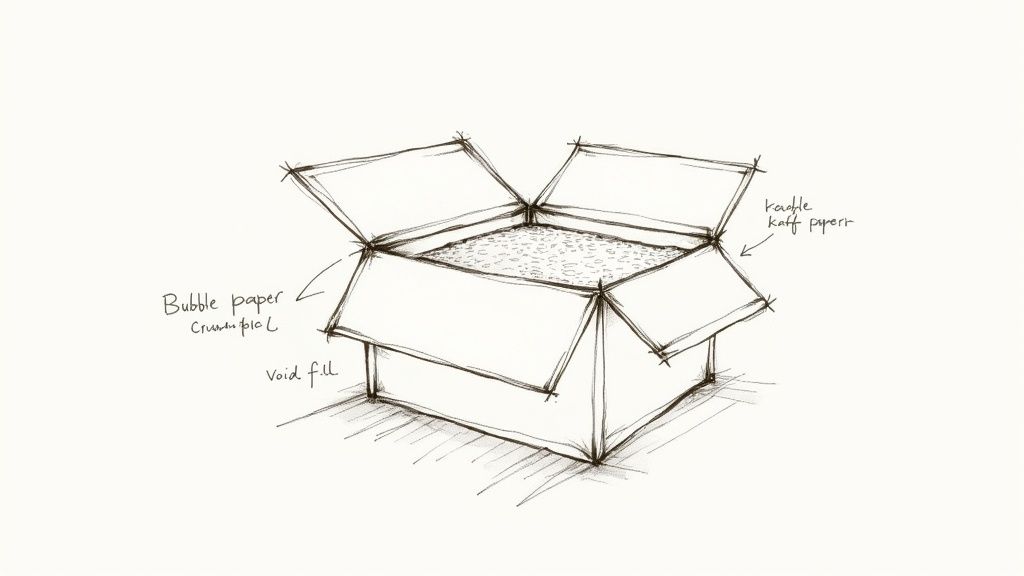

Mastering Protective Packing Materials and Techniques

Choosing the perfect box is only half the battle. What you put inside your shipping cardboard boxes is just as critical for making sure your items arrive in one piece. The empty space around your product, known in the trade as the 'void', is a major weak spot where damage can easily happen if it’s not dealt with.

Think of it this way: your product is the passenger, and the packing material is its seatbelt and airbag system. As it makes its way through the courier network, your box will be tilted, dropped, and stacked. Without the right internal protection, your item will slide about and slam against the box walls, risking all sorts of scuffs, dents, and breakages.

The real goal here is to completely immobilise the item. You want to create a protective cocoon that absorbs any shocks and stops it from moving an inch. When you master this step, you transform a simple container into a secure vessel, ready to take on the rough and tumble of transit.

Choosing Your Cushioning And Void Fill

You’ve got a wide range of materials to choose from for filling empty space and cushioning your goods, and each has its own strengths. Your final choice will probably come down to how fragile your item is, its weight, and what your budget looks like.

Bubble Wrap: This is the classic, go-to choice for anything fragile. Bubble wrap provides brilliant cushioning against bumps and bangs, as its air-filled pockets are fantastic at absorbing shocks. It's ideal for wrapping individual items like glass, ceramics, or electronics. For a more detailed walkthrough, you can check out our guide on how to pack fragile items with bubble wrap.

Packing Paper: Versatile and very cost-effective, kraft paper is perfect for scrunching up to fill gaps or for wrapping less fragile things to stop them getting scratched. It's also an eco-friendly choice that provides good, solid bracing.

Air Pillows: These are essentially small, inflatable bags of air that are incredibly lightweight. They're perfect for filling large empty spaces in your shipping cardboard boxes quickly and efficiently. Best of all, they add almost no weight to the parcel, which helps keep your shipping costs down.

Foam Peanuts: Sometimes called packing chips, these loose-fill pieces interlock to cushion items from every angle. They work really well for irregularly shaped products but can be a bit messy and aren't always the most sustainable option out there.

To help you decide, here’s a quick comparison of the most common options.

Comparing Protective Packing Materials

| Material | Best For | Cost | Eco-Friendly Rating |

|---|---|---|---|

| Bubble Wrap | Fragile items, shock absorption | Medium | ★☆☆☆☆ |

| Packing Paper | Void fill, scratch prevention | Low | ★★★★★ |

| Air Pillows | Filling large voids, lightweight | Medium-High | ★★☆☆☆ |

| Foam Peanuts | Irregularly shaped items | Medium | ★☆☆☆☆ |

Choosing the right material is a balancing act between protection, cost, and environmental impact. For everyday items, packing paper is a fantastic all-rounder, while high-value electronics will benefit from the superior cushioning of bubble wrap.

The most effective packing strategy often involves a combination of materials. Use bubble wrap for direct cushioning around the item, and then use packing paper or air pillows to fill the remaining void and brace the product firmly in place.

This layered approach ensures that the item is shielded from direct impact while also being held securely, preventing any movement inside the box.

Advanced Packing Techniques For High-Value Items

For items that are particularly fragile, heavy, or valuable, just filling the gaps might not be enough. You’ll need to step up your game with more advanced techniques to guarantee maximum protection.

One of the most effective methods is the box-in-box technique. This is exactly what it sounds like: you place your main item (cushioned, of course) inside one box, and then place that entire box inside a larger shipping box. You then fill the space between the inner and outer box with packing material like foam peanuts or air pillows.

This creates a brilliant secondary buffer zone. It means any external impact has to get through two layers of cardboard and two layers of cushioning before it even gets close to your product. It’s the gold standard for shipping delicate electronics, valuable antiques, or anything irreplaceable. For really specialised items, this expert guide on how to pack fragile items for moving can offer some priceless tips to prevent damage.

Another key technique is bracing. This involves using tightly crumpled paper, custom cardboard inserts, or foam blocks to wedge an item firmly in the centre of the box. This is especially important for heavy items that could otherwise crush softer void-fill materials and start to shift around. Proper bracing ensures the item’s weight is distributed evenly and it stays completely immobilised for the entire journey.

Choosing Sustainable Shipping Cardboard Boxes

Making sustainable choices isn't just a nice-to-have anymore; it’s something customers and businesses now expect. When you're choosing cardboard shipping boxes, looking beyond simple recyclability is how you make a real environmental difference. A genuinely eco-friendly box has a story behind it—one of responsible sourcing, minimal waste, and conscious production from forest to front door.

This move towards greener packaging isn't just a fleeting trend. The UK market for large cardboard boxes is on the rise, partly thanks to government policies that favour recyclable materials and sustainable business practices. This is driving innovation and making it much easier for businesses like yours to get on board.

Look for High Recycled Content

The single most impactful step you can take is to choose boxes made from a high percentage of recycled materials. Every box made from recycled content cuts down the demand for new tree pulp. That, in turn, helps conserve forests, saves water, and lowers the energy needed for manufacturing.

When you're sourcing your shipping boxes, find suppliers who are upfront about what their boxes are made from. Many standard boxes today contain over 70% recycled content, with some even reaching 100% recycled fibres. Choosing these options shows a genuine commitment to a circular economy, where materials get used again and again.

Understand FSC Certification and Inks

While recycled content is king, it's also worth thinking about where any new fibres come from. This is where the Forest Stewardship Council (FSC) steps in.

An FSC certification is your guarantee that any wood pulp used to make the box comes from a responsibly managed forest. It means the forest meets strict environmental, social, and economic standards.

Next, have a look at the inks used for printing your logo or handling instructions. Old-school, petroleum-based inks can release nasty volatile organic compounds (VOCs) and make recycling a headache. In contrast, water-based inks are a much cleaner, greener choice. They break down easily without releasing harmful chemicals, which means the cardboard stays fully recyclable.

Right-Sizing Is a Powerful Green Strategy

One of the most effective—and often overlooked—green habits is right-sizing. Using a box that’s far too big for your product is wasteful on several levels. First, it uses more cardboard than needed. Second, it means you have to cram it full of void fill just to stop the item from rattling around.

Even more importantly, oversized boxes are space-hogs in delivery vans. This inefficiency means fewer parcels fit on each vehicle, leading to more trips and a bigger carbon footprint for every single item you ship. By carefully matching your box to your product, you don't just cut down on material costs; you actively help reduce transport emissions. This principle is just as crucial when moving house, and you can find more tips in our guide to an eco-friendly house move.

Your Essential Pre-Shipment Checklist

Getting into a solid routine is the easiest way to avoid those common, and often costly, shipping mistakes. Think of this checklist as your final quality control before the parcel is out of your hands and on its way.

Running through these quick steps for every package ensures all your careful decisions—from picking the right box to adding the right amount of protection—come together for a secure, professional shipment. It's about building a reliable system that protects your goods every single time.

The Five-Step Dispatch Plan

Here’s a simple but incredibly effective checklist to use for every parcel you send out. Get these steps down, and you’ll know your shipping cardboard boxes are perfectly prepped for whatever the journey throws at them.

Select the Right Box

First things first, check the box itself. Is it the right size? You’re looking for a snug fit, but with about 5cm of buffer space all around the item. Most importantly, is it strong enough for the job? Stick to single-wall boxes for lightweight, tough items, but always upgrade to double-wall for anything heavy, valuable, or delicate.Wrap and Protect the Item

Before anything goes in the box, make sure it’s properly wrapped. Use bubble wrap for fragile things or packing paper for items that just need a bit of protection from scuffs and scratches. This initial layer is its first line of defence against knocks and vibrations in transit.Fill All Empty Space

Once your item is in the box, the next critical step is to get rid of any empty space. Tightly scrunch up packing paper, use air pillows, or add void fill to pack out every single gap. The goal is to make sure nothing can move. When you gently shake the sealed box, nothing should move or rattle inside. This stops your contents from sliding around and smacking against the inside of the box.

A silent box is a secure box. If you can hear your item moving, it means there's still a risk of damage. Take a moment to add more void fill until the contents are completely braced and silent.

Seal the Box Securely

Grab some strong packing tape and use the ‘H-taping’ method. This just means you tape down the main centre seam where the top flaps meet, and then run tape across both of the end seams. This simple technique reinforces all the weak points and stops the box from bursting open under pressure.Apply the Label Correctly

Finally, stick the shipping label on the biggest, flattest side of the box. Make sure it’s stuck down flat, with no wrinkles, and is easy to read. Try to avoid putting it over any seams, edges, or on top of your packing tape, as this can mess with the courier’s scanners. For a wider look at getting things ready for a big move, which involves more than just shipping, this ultimate moving house packing checklist is a great resource.

Common Questions About Shipping Cardboard Boxes

Even when you think you’ve got it all figured out, a few practical questions always seem to pop up right in the middle of packing. Getting a straight answer can be the difference between a smooth dispatch and a costly headache.

We’ve rounded up some of the most common queries we hear about shipping cardboard boxes to help you get those last-minute details sorted.

Can I Reuse Old Shipping Boxes?

Yes, you can—but you need to play detective first. A used box has already done a tour of duty in the courier network, which means its structural integrity might have taken a hit.

Before you give a box a second life, give it a quick MOT. Look for:

- Weak spots or softness: Give the walls and corners a firm press. If they feel spongy or give way easily, the box has lost its backbone and won’t protect what’s inside.

- Tears or punctures: Any hole or rip is a glaring weak point that’s just waiting to get bigger in transit.

- Water damage: Stains, discolouration, or warping are big red flags. A box that’s been damp is significantly weaker, even after it’s dried out.

If the box still feels solid, clean, and is fully intact, it should be fine for another journey. That said, if you’re shipping anything valuable or fragile, always use a new box. The small saving simply isn’t worth the risk.

What Is the Maximum Weight for a Single-Wall Box?

There’s no single industry-wide rule, but a good rule of thumb is to keep the contents of a single-wall box under 10kg (around 22 pounds). This ensures the box can handle the weight without buckling at the seams, especially when it ends up at the bottom of a stack in a delivery van.

For anything heavier, or for smaller items that are particularly dense, it’s time to upgrade to a double-wall box. That extra layer of corrugated cardboard provides the muscle needed to manage the load and stop it from getting crushed.

A box’s strength isn’t just about what it can hold. It’s about how well it resists the crushing force of all the other parcels piled on top of it. That’s where a double-wall box really earns its keep.

What Is the Best Way for a Small Business to Buy Boxes?

For small businesses, it’s all about striking that perfect balance between cost and quality. The smartest move is usually to buy in bundled quantities or small bulk packs. Almost all suppliers will give you a much better price when you buy packs of 25, 50, or 100 boxes compared to buying them one by one.

Figure out the two or three box sizes you use most often and order those in bundles. This approach covers the bulk of your orders and gets you the best value for money. It keeps your initial costs down while lowering your per-unit price, helping you manage cash flow without ever skimping on the quality of your shipping cardboard boxes. As you grow, you can then start looking at larger wholesale orders to save even more.

At The Box Warehouse, we make it simple to find the perfect packaging for any job, whether you're sending one parcel or a thousand. Explore our extensive range of high-quality, durable shipping boxes and packing supplies today. Find everything you need in one place at https://www.theboxwarehouse.co.uk.