Published on : 29 November 2025

Shrink Wrap a Pallet Like a Pro A Complete Guide

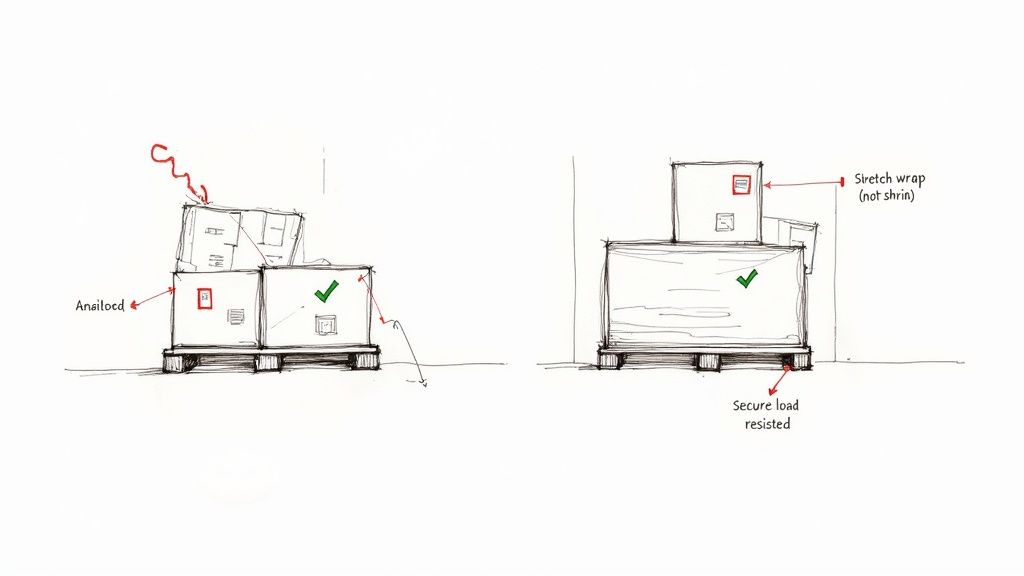

When you're getting ready to wrap a pallet, the first steps are stacking it properly and then wrapping it with stretch film—not the heat-shrinkable kind. You'll need to aim for at least a 50% overlap and pull the film tight to create strong tension. This simple but crucial process is what turns a wobbly tower of boxes into a single, solid unit, protecting your goods from the bumps and scrapes of shipping and handling.

It’s the final, essential step for getting your items from A to B safely and efficiently.

Why Proper Pallet Wrapping Is Non-Negotiable

Before you even pick up a roll of film, it's worth taking a moment to understand what's really at stake here. Wrapping a pallet isn't just about making it look tidy; it’s a critical job that protects your goods, the people handling them, and ultimately, your bottom line. It’s the difference between a successful delivery and a costly, dangerous mess.

One of the biggest points of confusion is the name itself. While many people search for how to "shrink wrap a pallet," the material almost always used for logistics is actually stretch wrap or stretch film. True shrink wrap needs a heat source, like a heat gun, to shrink down and mould itself to an object. As you can imagine, that’s not practical—or safe—for a large pallet stacked high with goods. Stretch wrap, on the other hand, is designed to stretch and cling, using tension to hold everything together.

Stretch Wrap vs Shrink Wrap: What You Really Need for Pallets

To clear things up, let's break down the key differences. For pallet wrapping, there’s a clear winner.

| Feature | Stretch Wrap (Stretch Film) | Shrink Wrap (Shrink Film) |

|---|---|---|

| Application | Stretched and pulled tight around the load. No heat needed. | Applied loosely, then heated to shrink and conform. |

| Purpose | To unitise and secure a load through tension and cling. | To create a tight, protective, tamper-evident covering. |

| Equipment | Can be applied by hand, with a dispenser, or by machine. | Requires a heat gun or a heat tunnel. |

| Best For | Securing boxes on a pallet for transport. | Protecting individual items, creating multi-packs. |

| Material | Highly stretchable linear low-density polyethylene (LLDPE). | Typically polyolefin or PVC, which shrinks with heat. |

Ultimately, for securing pallets, stretch wrap is the industry standard and the right tool for the job.

The True Purpose of Stretch Wrapping

The real goal here is to unitise the load. That's just a technical way of saying you’re turning dozens of separate boxes into one solid, stable block. This is what stops items from shifting, toppling over, or completely collapsing during the inevitable jolts and vibrations of transit. A well-wrapped pallet can handle the forces of a lorry accelerating, braking, and turning, ensuring everything arrives looking exactly as it did when it left.

This isn't just about being careful; it's a fundamental part of cargo safety. The importance of properly securing loads is even backed by official guidelines like the FMCSA Load Securement Regulations, which set the rules for transporting cargo safely.

A poorly secured pallet isn't just a risk to your products; it's a significant safety hazard in warehouses and on the road. Unitising the load correctly is your first line of defence against accidents and financial loss.

The logistics industry in the UK absolutely relies on stretch films, and it's a massive global market. In fact, the global stretch wrap market was valued at around USD 3.3 billion in 2025, a figure driven by the boom in e-commerce and the need for stricter shipping standards.

Whether you're moving house, putting things into storage, or running a small business, understanding the top uses of pallet wrap shows just how versatile it is. Mastering this skill is a simple way to protect your valuables and make sure they get where they're going in one piece.

Choosing the Right Film for Your Load

Picking the right stretch film is about more than just grabbing the nearest roll. The film you choose is the single most important factor in keeping your pallet stable, and getting it wrong can lead to wasted materials, damaged goods, and a failed shipment. The type of film, how it’s made, and its thickness all play a huge part in how well your pallet holds up.

Think of it like choosing tyres for a car—you wouldn't put racing slicks on for a snowy day. In the same way, you shouldn't use a lightweight cast film for a pallet stacked with heavy, sharp-edged machine parts.

Cast Film vs. Blown Film

In the world of stretch film, you’ll mainly come across two types: cast film and blown film. The names come from how they’re made, and each one has its own strengths, making them suitable for different jobs.

Cast Film: This is made by pushing heated resin through a flat die onto a chilled roller. The process gives it fantastic clarity, so you can easily read barcodes or product labels right through the wrap. It’s also much quieter to unwind, which is a big relief in a busy warehouse. The downside? It doesn't have the same puncture resistance as blown film.

Blown Film: Made by blowing heated resin into a bubble, this film is tougher and far more resilient. It offers top-notch puncture and tear resistance, making it the best choice for securing loads with sharp corners or uneven shapes. The trade-offs are that it’s usually a bit more expensive, not as clear, and makes more noise when you apply it.

For most day-to-day jobs, like stacking uniform boxes for a house move or sending out a standard retail shipment, cast film is a great, cost-effective option. But if you’re wrapping anything heavy, awkward, or with pointy bits, investing in blown film is cheap insurance against a collapsed pallet.

Matching Film Gauge to Your Load

The film's thickness, known as the gauge (or micron, µm), is directly tied to its strength and how much it can stretch. Using a film that's too thin for a heavy load is just asking for trouble.

Here’s a practical guide to get you started:

- Light Loads (up to 500kg): For light, evenly stacked loads like boxes of clothes or empty containers, a film of 60-70 gauge (15-17µm) is usually all you need.

- Medium Loads (500-1,000kg): For your more standard, heavier loads like tinned goods or electronics, an 80 gauge (20µm) film offers a solid balance of strength and value.

- Heavy or Irregular Loads (over 1,000kg): For bulky machinery, building materials, or pallets with sharp corners, you’ll want a heavy-duty 90-150 gauge (23-38µm) film for maximum hold and puncture resistance.

The UK market really reflects this, with mid-range thicknesses between 15µm to 25µm making up over 44% of all film used, simply because they're so versatile. The entire UK stretch film market is growing fast, thanks to the boom in e-commerce and logistics, which just goes to show how vital good wrapping solutions are. If you’re interested, you can explore the market projections and analysis.

Pro Tip: Don’t just assume thicker is always better. A common mistake is to over-spec your film, which just wastes money and plastic. Take a moment to analyse your typical load weight and shape to find the sweet spot for your needs.

Eco-Friendly and Pre-Stretched Options

Finally, it’s worth looking at some of the more modern, sustainable films out there. Pre-stretched film is a game-changer. It’s stretched almost to its breaking point during manufacturing, which means you use far less film and much less effort to get a really secure wrap. This helps cut down on both your costs and your plastic waste.

You can find a great selection of standard and pre-stretched pallet wrap options to suit different jobs. These clever films are becoming more and more popular as businesses look for ways to reduce their environmental footprint without sacrificing performance.

Mastering the Manual Wrapping Technique

For smaller businesses, one-off shipments, or even a big house move, knowing how to wrap a pallet by hand is an invaluable skill. It might look simple, but there's a real technique to it. The difference between a solid, secure load and a wobbly disaster often comes down to getting the basics right.

A good wrap ensures all your careful stacking pays off, delivering a professional result without needing any fancy machinery.

Anchoring and Applying the Film

Before you even touch the stretch film, your foundation is everything. A well-stacked pallet, with heavier items at the bottom and the weight spread evenly, gives you the stable core you need. Try to interlock boxes in a brick-like pattern to stop them from forming columns that can easily fall over.

Your first move is to anchor the film directly to the pallet. Don’t just tie it to a box on top. Instead, thread about a metre of film through a corner of the pallet base and tie a proper knot. This locks the entire load to the pallet right from the start, which is critical for preventing it from sliding off in transit.

Once you're anchored, always walk backwards around the pallet while facing the load. This lets you use your body weight to keep the film tight and maintain consistent tension—the secret to a secure wrap. Pull the film taut as you go, applying firm, steady pressure. If it feels loose at any point, it’s not doing its job.

To build up real strength, each new layer of film should overlap the one before it by about 50%. This creates a strong, unified web of support around your goods. Think of it like applying a bandage; that overlap is what gives it structural integrity. Pay extra attention to the corners, as they’re always the most vulnerable spots.

A classic mistake is walking forwards. It feels more natural, but it makes it almost impossible to maintain the right tension. Walking backwards gives you the leverage you need to pull the film tight, creating the force that holds everything together.

This infographic breaks down the key things to consider when you're getting ready to wrap a pallet.

It’s a handy visual guide to help you quickly match your load with the right film and thickness, ensuring a secure wrap from the get-go.

Common Hand Wrapping Mistakes and How to Fix Them

Even with the best intentions, it's easy to make a few common mistakes when you're wrapping by hand. Here’s a quick troubleshooting guide to spot and fix them.

| Mistake | What It Looks Like | How to Correct It |

|---|---|---|

| Loose Wrap | The film is baggy or can be easily pushed in with a hand. The load might wobble. | Walk backwards, pulling the film taut with consistent pressure. Use your body weight for leverage. Re-wrap if necessary. |

| Not Anchoring to Pallet | The entire wrapped load can shift or slide on the pallet base. | Unwind the film and re-anchor it by tying it directly through a corner of the wooden pallet itself, not just to a box. |

| Uneven Overlap | There are gaps between layers of film, or the overlap is less than 50%. The wrap looks inconsistent. | Slow down and consciously aim for a consistent 50% overlap with each rotation. This creates a stronger, unified wrap. |

| Weak Corners | The film on the corners is thin, torn, or not pulled tight, leaving goods exposed. | Add extra wraps around the corners. Consider using corner or edge protectors under the film for sharp-edged loads. |

| Walking Forwards | You're facing the direction you're walking, making it hard to pull the film tight. | Always face the pallet and walk backwards. This posture is essential for maintaining proper tension throughout the wrap. |

Getting the technique right just takes a bit of practice. Keep these points in mind, and you'll be wrapping like a pro in no time.

Finishing with Reinforcement

For maximum stability, it’s a great idea to create a reinforcing "rope" at the top and bottom of the pallet. It’s easy to do. As you complete the final few wraps around the base, just twist the film into a thick, rope-like strand. Do the same thing again at the top. This concentrated band of film acts like strapping, adding extra strength where a load is most likely to shift.

Wrapping by hand involves a lot of repetitive motion, and a simple tool can make a world of difference. For smaller jobs or bundling items together, a quality mini pallet wrap dispenser can save your hands from friction burns and help you apply the film more efficiently.

Once you’re finished, tear the film and neatly tuck the last metre or so underneath one of the existing layers on the side of the pallet. A well-tucked end won’t unravel during shipping, which means all your hard work will hold up until your goods reach their destination.

Using a Wrapping Machine for Speed and Consistency

When your shipping volume starts to climb, hand wrapping becomes a real bottleneck. It’s physically exhausting, takes up a lot of time, and getting a perfectly consistent wrap every single time is a massive challenge. This is where a wrapping machine completely changes the game. It turns a manual chore into a quick, streamlined, and efficient part of your operation.

For any business looking to scale up, machines deliver incredible speed and reliability. They ensure every pallet gets the same professional, secure wrap, which is vital for protecting your goods and maintaining your reputation. The initial cost quickly pays for itself through lower labour costs, much less film wastage, and fewer damaged shipments.

Understanding Pallet Wrapping Machines

You don't need a giant, fully automated system to feel the benefits. Most small to medium-sized businesses find their sweet spot with semi-automatic machines. These offer a huge upgrade in efficiency without the hefty price tag of industrial robotics.

Here’s a quick rundown of the most common types you’ll come across:

- Turntable Wrappers: These are the most popular style for a reason. You simply place the pallet on a rotating platform, attach the film, and the machine spins the pallet as a film carriage moves up and down. They’re efficient, easy to get the hang of, and perfect for standard pallet loads.

- Rotary Arm Wrappers: With these machines, the pallet stays still while an arm rotates around it. This is ideal for very heavy, light, or unstable loads that might shift or topple on a turntable.

If you're seriously considering an automated solution, it’s worth doing your homework. You can explore a detailed guide to pallet shrink wrap machines to get a much deeper understanding of the options available and figure out what might fit your operation best.

Dialling in the Perfect Wrap

The real magic of a machine is how it controls the two most important variables: film tension and coverage. Getting these settings just right is the key to maximising both your film efficiency and the security of your load.

Film Tension and Pre-Stretch

Most modern machines come with a pre-stretch function. This is a brilliant system of rollers that stretches the film before it even touches the pallet, often by 200-300%. What does that mean in real terms? You can turn one metre of film into three or four, dramatically cutting your material costs while creating a much stronger hold. You’ll just need to set the tension correctly—too loose and the load will shift; too tight and you risk crushing your boxes.

Turntable Speed and Wrap Count

By adjusting the turntable speed, you control how much the film overlaps with each rotation. A slower speed gives you more overlap for a stronger wrap, which is exactly what you want for the base and top of the pallet. A great feature is being able to program the machine to apply a set number of wraps at the bottom (usually three to five), a single layer through the middle, and then another three to five reinforcing wraps at the top.

Programming your machine for a 'bottom-up-down' cycle is standard practice in the industry. It makes sure the most vulnerable parts of the load—the base where it meets the pallet and the very top layer—are double-wrapped for maximum security.

With a machine, you can confidently wrap a pallet knowing it’s ready for whatever the supply chain throws at it. A few minutes spent fine-tuning the settings will deliver a perfect, cost-effective wrap every single time.

Critical Safety Checks and Common Mistakes to Avoid

A poorly wrapped pallet isn’t just a financial risk—it’s a genuine safety hazard waiting to happen. Before you let that pallet go, running through a final quality check is absolutely essential. This last once-over ensures your load is stable, secure, and ready for the bumps and knocks of transport, protecting both your products and the people handling them.

Many problems come from just a few common, easily avoidable mistakes. A big one is failing to properly anchor the film to the pallet itself. If the wrap is only clinging to the boxes, the entire load can slide right off the base during a sudden stop or turn. It’s a simple fix that makes all the difference.

Top Wrapping Errors and How to Spot Them

Knowing what a bad wrap looks like is the first step to fixing it. Keep an eye out for these tell-tale signs:

- Not Enough Overlap: Can you see gaps between the layers of film? That’s a red flag. You should be aiming for at least a 50% overlap on every rotation to create a strong, interlocking web around your goods.

- Wrong Tension: If you can easily push your hand into the side of the pallet and feel a lot of give, the film is far too loose. The wrap needs to be drum-tight to hold everything in place.

- Forgetting the Base: The first three to five wraps at the bottom are the most important. They absolutely must bind the lowest layer of boxes directly to the pallet, which is what stops the whole load from shifting.

Another classic mistake is getting the film gauge wrong. Using a film that's too thin for a heavy or sharp-edged load is just asking for punctures and tears, which will instantly compromise the wrap’s integrity.

A pallet is only as strong as its weakest point. A single tear or loose section can unravel, leading to a shifted load, damaged goods, and potential accidents in a warehouse or on the road.

Essential Personal and Workspace Safety

When you're wrapping a pallet, especially by hand, your safety comes first. It can be a surprisingly physical job, and a few simple precautions can prevent common injuries.

Always keep your work area clear of clutter. You need a clean, open path to walk backwards around the pallet without tripping over stray boxes or equipment. When you’re lugging around those heavy, industrial-sized rolls of film, use proper lifting techniques—bend at the knees, not your back—to avoid painful strains.

Friction burns from the film roll spinning in your hands are also more common than you'd think. A good pair of work gloves will give you the protection you need and improve your grip, letting you apply that all-important tension safely.

Finally, for fragile or high-value items, don’t forget to label the pallet clearly. Using the right caution and warning labels ensures handlers know to treat your shipment with the care it deserves.

Pallet Wrapping FAQs

Even with the best guide in hand, questions always pop up when you're in the middle of a job. We get it. That's why we've put together answers to some of the most common queries we hear about how to shrink wrap a pallet. Think of this as your quick-reference guide for troubleshooting on the fly.

Getting these details right is what separates a stable, secure load from a potential disaster. From how many times to wrap the film to dealing with awkward shapes, here’s what you need to know.

How Many Times Should You Wrap a Pallet?

This is easily the most common question, and the answer really depends on the load itself.

As a solid rule of thumb, start with three to five wraps around the very base. This is crucial for locking the goods directly to the pallet. After that, work your way up, making sure each layer has at least a 50% overlap. Finish off with another three to five wraps at the top to secure everything.

If you’re dealing with a particularly heavy or wobbly load, don't be shy about adding more. Some logistics pros will use as many as ten complete wraps for maximum security. It’s always better to use a bit of extra film than to risk a pallet collapsing mid-journey.

What Is the Best Way to Wrap an Irregularly Shaped Pallet?

Wrapping a pallet stacked with uneven or oddly shaped items is a classic challenge. The trick is to create a more uniform surface before you even pick up the wrap.

Use dunnage—things like bubble wrap, spare cardboard inserts, or even old blankets—to fill any significant gaps or voids. Your goal is to turn that jumble of shapes into something closer to a cube.

Once you’ve evened things out, the wrapping process is the same. Just be extra mindful of keeping firm, consistent tension on the film. This helps pull all the separate items together into one solid block. You might also need to add extra layers over sharp corners or pointed edges to stop the film from tearing.

Remember, the goal of stretch wrap is to unitise the load—turning many separate items into one solid block. For irregular loads, filling voids is the crucial first step to achieving this.

This simple prep work gives the film a consistent surface to cling to, which means no loose spots and much less chance of the load shifting.

How Much Weight Can a Wrapped Pallet Hold?

This is a bit of a trick question. The pallet wrap itself doesn't actually determine the weight limit—the pallet does.

A standard UK wooden pallet is typically rated to hold around 1,000kg. Your job when you shrink wrap a pallet isn't to increase that capacity, but to make sure the load remains stable and secure right up to that limit. A proper wrap is what stops the items from shifting, which is what maintains the pallet's integrity during handling and transit.

For a deeper dive into common queries, our complete guide to frequently asked questions covers a wide range of packaging topics.